From Europe to the United States, the journey of innovation continues. In 2025, De Angeli Prodotti will take center stage at Coiltech Deutschland and Coiltech North America, bringing the best of its technologies for e-mobility.

The future of mobility is electric, and even though today it still seems like a distant future for non-experts, it is essential that the key players in the energy transition deploy all their innovations to bring it closer in time. As we have written in recent years, thanks to our investments in researching materials, technologies, and processes to solve the problems that slow down the mass introduction of e-mobility, we find ourselves in a situation of urgency. For this reason – during our participation in two important international trade fairs dedicated to electromechanics and innovation in electrical systems such as Coiltech Deutschland 2025 and Coiltech North America 2025 – we decided to present advanced solutions for electric motors, transformers, generators, and other applications in e-Mobility.

Summary:

- 1. An industrial vision oriented towards electrification

- 2. Coiltech: an international showcase and a space for technical dialogue

- 3. The value proposition for electric automotive

- 4. Ongoing research and tailor-made customization

- 5. Conclusion

1. An industrial vision oriented towards electrification

De Angeli Prodotti, active in e-mobility since 2018, develops advanced solutions for transport electrification with a focus on efficiency, miniaturization, and sustainability. Present at the trade show with a dedicated area, it showcased CTC cables, Litz wires, flat enameled conductors for hairpin windings, and other special conductors for the automotive sector. Since 2022, it has been IATF 16949 certified – a key requirement for collaborating with automakers and Tier 1 suppliers. The company has also launched a production facility for PAI wires, ideal for compact, automated windings in permanent-magnet motors, helping to innovate electric mobility with high-performance, reliable components.

2. Coiltech: an international showcase and a space for technical dialogue

With 236 booths already reserved for its inaugural edition, Coiltech North America 2025 is gearing up to become the premier event for professionals in the electric motors, transformers, and generators sector. The fair will take place on June 11 and 12 in Novi, Michigan, in the heart of the Detroit metropolitan area—a strategic region for manufacturing and technological innovation in the United States. It represents a unique opportunity to bring together the entire electromechanical supply chain under one roof, creating synergies and collaboration opportunities among manufacturers, component suppliers, engineers, and decision-makers. The accessibility of the location, combined with the United States’ growing focus on energy efficiency and grid modernization, makes Coiltech North America an ideal catalyst for the country’s technological development and energy autonomy.

Meanwhile, in Europe, the third edition of Coiltech Deutschland concluded successfully, held on March 26 and 27, 2025, at the modern Messe Augsburg exhibition center in Augsburg, Bavaria. Once again, this year the fair confirmed its position as a benchmark in the European electromechanical landscape, drawing hundreds of exhibitors and thousands of specialized visitors from across Europe.

With two annual events in the world’s key markets, Coiltech has solidified its position as an international hub for technological exchange and innovation across the entire electromechanical industry. One of Coiltech’s most appreciated aspects is its compact format, designed to encourage direct, concrete, and productive meetings between suppliers, designers, and purchasing managers. In a single day, it is possible to visit the entire exhibition layout, organized in a clear and functional manner. Unlike generalist trade fairs, Coiltech focuses entirely on specialization and high-level professional exchange.

During the two days of Coiltech Augsburg 2025, De Angeli Prodotti’s booth served as a meeting point for engineers, designers, buyers, and OEMs from across Europe and beyond. The company was able to demonstrate live how its conductors operate, engage with the new challenges posed by the miniaturization of electric motors, and explore the evolving needs of the industrial market.

3. The value proposition for electric automotive

The electric automotive sector is among the most demanding in terms of technical requirements: thermal resistance, chemical compatibility, tight dimensional tolerances, and long-term reliability are just some of the required elements. De Angeli Prodotti has developed a complete range of special conductors precisely to meet these needs.

3.1 CTC – Countinuously Transposed Cables

De Angeli Prodotti’s CTC (Continuously Transposed Cables) are compact conductors made of multiple enameled wires interwoven continuously. This technology ensures a uniform current distribution, reduces losses from skin and proximity effects, and enhances both efficiency and thermal performance in transformers. The CTCs are custom-designed to meet customer requirements and are ideal for use in power transformers due to their reliability, compactness, and ease of processing.

- Aluminum CTC: an innovative solution that combines the advantages of transposed cable technology with the lightness and cost-effectiveness of aluminum. Ideal for large transformers, this conductor allows cost reduction without compromising electrical performance. It offers good current distribution, lower skin and proximity effect losses, and optimal heat management. It is custom-designed to meet customer requirements, representing a valid alternative to copper in projects where weight and cost are critical factors.

- CTC LTE: a transposed cable with low-thickness enamel coating, designed to maximize the conductive area inside transformers. Thanks to an innovative ultra-thin enamel system, it allows increasing the copper cross-section without changing dimensions, improving electrical conductivity and energy efficiency. This technology reduces losses and optimizes thermal performance while maintaining high standards of insulation and reliability. The CTC LTE is ideal for high-efficiency transformers and represents an advanced solution for those seeking high performance in compact spaces.

- CTC ETP-Plus: a high-conductivity copper transposed cable developed to improve transformer efficiency. Made with enhanced Electrolytic Tough Pitch (ETP) copper, it offers superior conductivity compared to traditional standards, reducing electrical losses and improving thermal performance. This solution optimizes material usage, increasing energy efficiency without altering production processes. The CTC ETP-Plus is ideal for high-performance applications where reliability, efficiency, and sustainability are essential.

3.2 Bare conductors

De Angeli Prodotti’s bare conductors are copper or aluminum wires without insulation, used for electrical and mechanical applications where a coating is not required. They offer excellent conductivity, mechanical strength, and versatility, making them ideal for windings, internal connections, and grounding. Available in various shapes (round, flat, or custom-profiled) and cross-sections, they can be tailored to customer requirements. The quality of the materials and precision in manufacturing ensure high performance even under complex operating conditions.

- Oxidized litz wire: a conductor composed of fine enameled wires, designed to reduce skin and proximity effect losses at high frequencies. Thanks to controlled surface oxidation, it improves wire adhesion and ensures greater thermal and mechanical stability. It is ideal for applications in high-frequency transformers, inductors, motors, and generators, where high electrical performance and compact size are required. Customizable according to customer specifications, it represents an advanced technological solution for increasing efficiency in electromagnetic devices.

3.3 Thervest enamelled flat wires

The Thervest® enameled flat conductors from De Angeli Prodotti are copper or aluminum conductors coated with thermosetting enamels, designed for extreme environments with thermal, electrical, and mechanical stresses. They represent a well-established and competitive solution, particularly appreciated by OEMs and Tier 1 suppliers for their ease of processing and reliability. The range includes versions tailored for demanding requirements, such as Thervest® 240, which uses a polyimide enamel characterized by low dielectric permittivity even at high temperatures—ideal for applications that require resistance to partial discharges and high dielectric performance.

3.4 PEEK extruded flat wires

Peekvest is the extruded PEEK flat wire developed by De Angeli Prodotti for E-Mobility applications, where operating voltages exceed 800 V. Made from polyether ether ketone, it is resistant to partial discharges, cooling oils, high temperatures, and mechanical stresses. It is self-lubricating, easy to process, and delivers exceptional dielectric performance. Its manufacturing process is solvent-free, contributing to sustainability. Peekvest represents a premium solution for windings in critical environments, addressing automakers’ evolving demands for efficiency, reliability, and innovation.

3.5 Polyimide-FEP wrapped flat wires

The Polyimide-FEP wrapped flat wires from De Angeli Prodotti are designed for E-Mobility applications with operating voltages above 800 V. Manufactured using a sintered tape-winding process, they ensure excellent adhesion thanks to a specialized adhesive, making them suitable for complex configurations such as hairpin-style bends. They offer one of the highest resistances to partial discharges on the market – comparable to PEEK – and exhibit excellent compatibility with cooling oils. This advanced solution meets the safety, flexibility, and high-performance requirements demanded by OEMs and Tier 1 suppliers, representing a technologically reliable option for the evolution of E-Mobility.

3.6 Litz cables

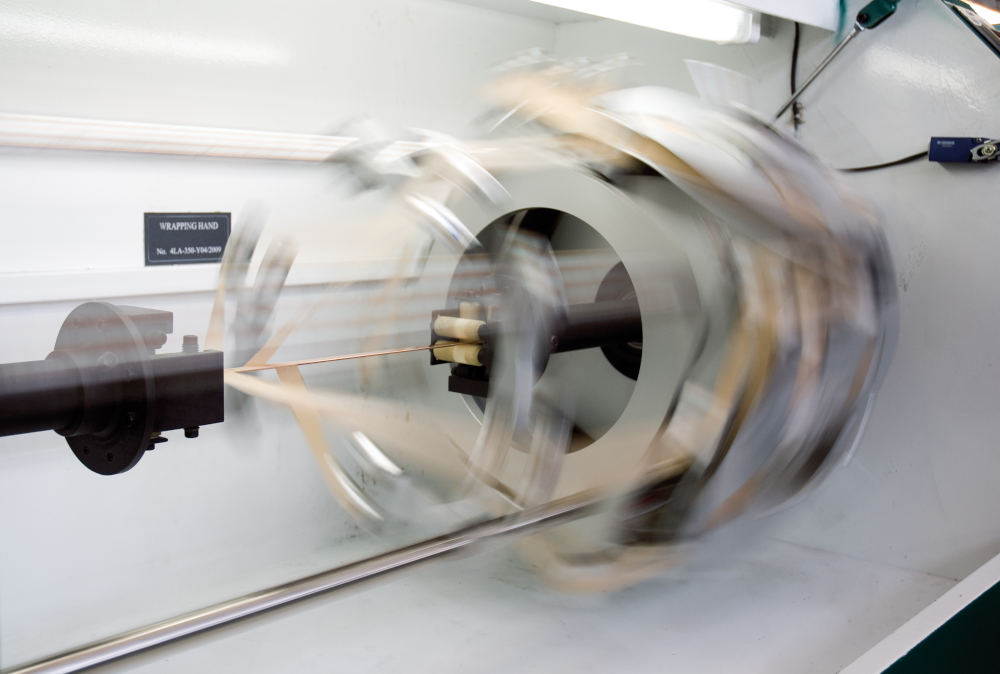

De Angeli Prodotti’s Litz Wires are conductors made up of numerous individually enameled strands, woven according to optimized geometries to reduce skin and proximity effect losses in high-frequency applications. Each strand can be insulated with specific enamels or tapes, while the finished cable can take on wave, braid, or rope configurations. The product ensures maximum design flexibility: geometries, types of enamel, and external insulations can be selected based on the application. These solutions are fully customizable to meet specific electrical, thermal, and mechanical requirements of advanced electromagnetic components.

3.7 Enameled copper and aluminum conductors

De Angeli Prodotti’s enameled conductors are copper or aluminum wires coated with thermosetting enamels applied continuously and in a controlled manner. Designed to optimize the enamel thickness in microns and the wire’s weight within the winding, they reduce production waste. They offer advantages over tape-wound conductors: thinner insulation, greater winding density, and lower weight of the finished component. Available in various geometries and with a wide selection of enamels to meet electrical, mechanical, and thermal requirements, they can be customized for OEMs and Tier 1 suppliers in the motor, transformer, and e-mobility sectors.

3.8 Paper wrapped conductors

De Angeli Prodotti’s paper wrapped conductors are copper or aluminum wires or flat strips coated with one or more layers of insulating tape applied under precise control. The materials available for the tape include polyester, polyimide, kraft paper, and mica, chosen based on the application’s requirements. The process ensures uniform thickness, optimal adhesion, and high-quality insulation. The product is fully customizable in terms of conductor shape, insulating material type, and number of layers, according to the customer’s specific needs.

- Mica wrapped conductors: these are copper or aluminum wires or flat strips coated with tapes made of natural or synthetic mica bonded to materials such as glass or polyester. They are designed to ensure electrical insulation and fire resistance in high-reliability applications such as motors, transformers, and generators. The production process guarantees high coating quality and excellent adhesion, with customization available upon customer request.

4. Ongoing research and tailor-made customization

Among our company’s main competitive advantages is undoubtedly the ability to co-design with the customer, made possible by the extremely high investments we have made over the years in research, which allow us to develop truly bespoke solutions that we test in our in-house laboratories, ensuring their longevity and efficiency through long, unpredictable life cycles.

Our internal Research and Development department not only focuses on optimizing the electrical and mechanical performance of materials, but also on improving their suitability for automated processing, an essential aspect in an industry that is increasingly automated and efficiency-driven.

5. Conclusion

With participation at Coiltech Deutschland 2025 and an upcoming presence at Coiltech North America, De Angeli Prodotti reinforces its role as a technological partner in the transition to electric mobility. Our company brings forward an advanced portfolio of conductors designed to meet the specific needs of traction, storage, and conversion. Each solution is born from continuous dialogue with customers and a deep understanding of industry dynamics. Certifications such as IATF 16949, a focus on sustainability, and our co-design capabilities make De Angeli Prodotti a reference point for those building the mobility of tomorrow.