Introduction

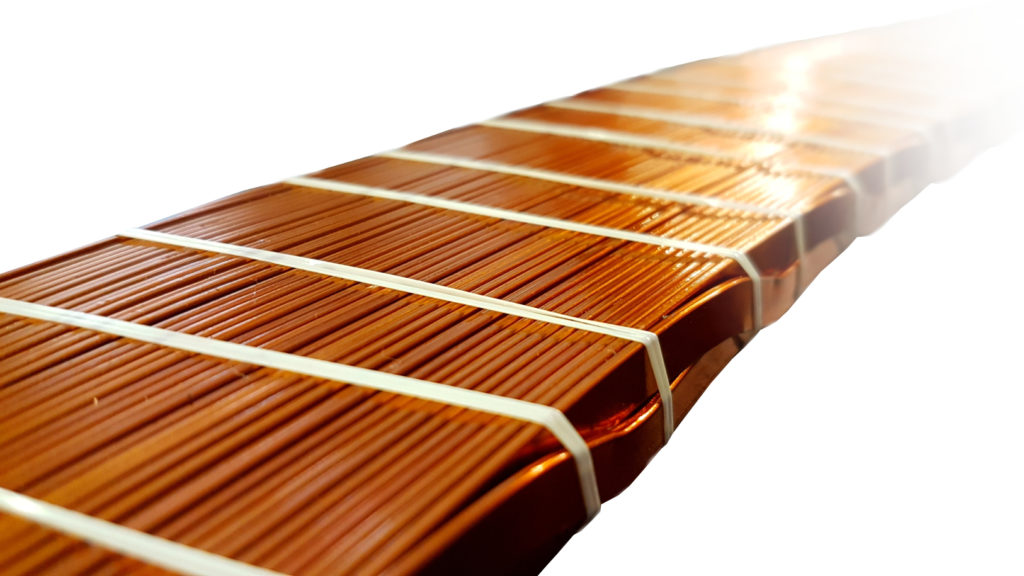

Transposed cable or Continuously Transposed Conductor (CTC) is the most used for windings on power transformers.

It consists of a group of enameled rectangular wires, usually with PVF (polyvinylformal) enamel, which are transposed to create a kind of rectangular strand.

In the CTC, each elementary conductor consecutively and repeatedly assumes every possible position inside the cable.

The bundle of strips can be wrapped and insulated with tapes, generally in pure cellulose paper.

Engineering

The transposition of the elementary conductors allows the creation of a very flexible product, able to adapt perfectly to the winding, with a significant reduction in electrical losses for the same section, compared to a solid conductor. By acting on the number of units (strips) composing a CTC, various advantages can be obtained for use in the transformer.

De Angeli Prodotti produces a wide range of CTCs both in copper and aluminum, in all possible configurations.

| Elementary conductors | Cu | Al |

| Strip width [mm] | 2,5 ÷ 12,5 | 5,0 ÷ 12,5 |

| Strip thickness [mm] | 0,8 ÷ 3,25 | 1,5 ÷ 3,25 |

| W/T ratio | ≥ 2,5:1 ÷ ≤ 7,5:1 | ≥ 2,5:1 ÷ ≤ 7,0:1 |

| Section of elem. conductor [mm²] | 4,35 ÷ 35 | 8,0 ÷ 35 |

The elementary conductors are insulated with enamels in thermal class from 120 to 200 ° C and, on request, self-adhesive epoxy resin is available, even one-sided (radial).

| CTC | Cu | Al |

| No. of strips | 5 ÷ 85 | 5 ÷ 85 |

| Axial max [mm] | 6 ÷ 27 | 8 ÷ 27 |

| Radial max [mm] | 5 ÷ 80 | 5 ÷ 80 |

CTCs can be subsequently insulated with a variety of tapes – from pure cellulose kraft paper, to thermo-stabilized paper or micro-crepe – or with better performing insulators such as polyesters and aramids for higher thermal classes.

Advantages

Increasing the number of strips for a CTC, it is possible to subdivide the conductor’s area even more than in the single configuration.

The current flow is distributed over a plurality of elementary conductors and, in other words, there is the “fragmentation” of the cross section of the conductor, which allows:

- Reduce electrical losses

- Increase the flexibility in winding

- Optimize the size of the winding.

Increasing the efficiency of the transformer and reducing its manufacturing cost.

Image Gallery

Download

Depilant_CTC_2017 vertical_align_bottomDownload PDF