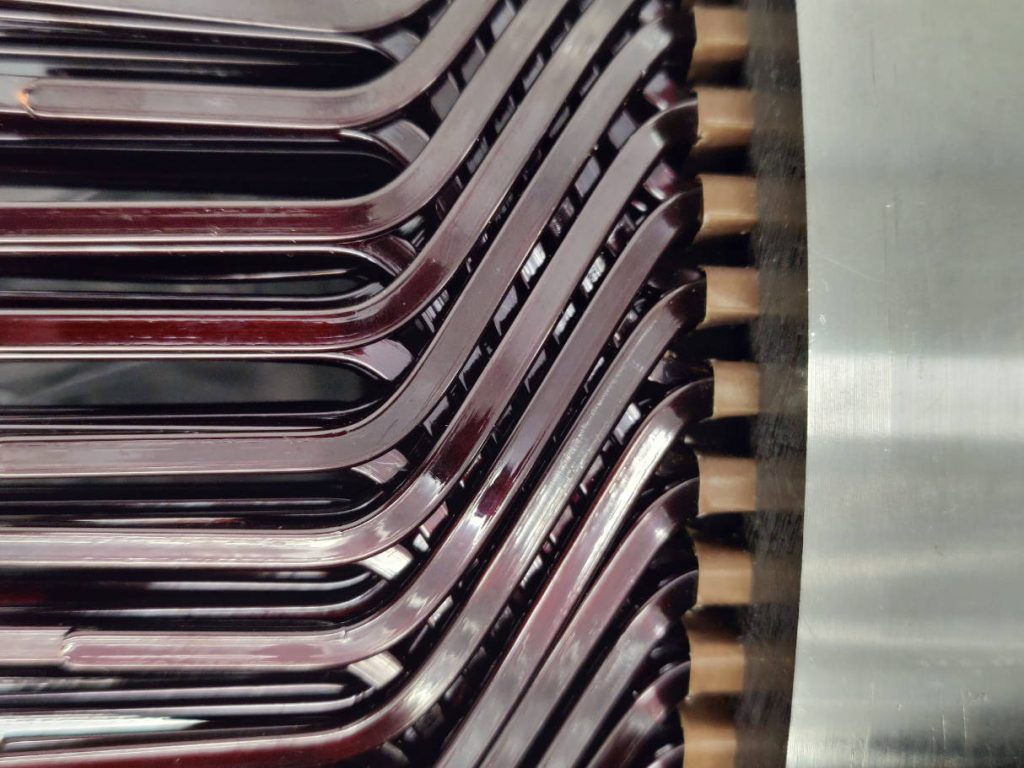

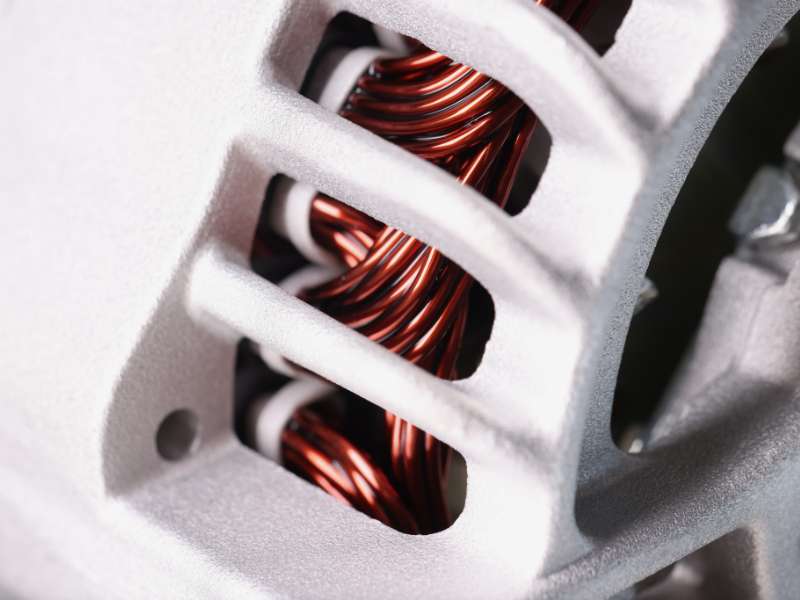

The continuous evolution of electric motors requires cutting-edge solutions, in particular when it comes to operating voltages that reach 800 V and above. This growing challenge highlights the need for windings that not only meet dielectric requirements but also excel mechanically and chemically.

The De Angeli Prodotti philosophy has always been that of diversification, believing that there will not be a single solution capable of covering the entire E-mobility market. Therefore, we are committed to providing a complete range of electric motor winding products, capable of responding to the growing challenges of technological evolution.

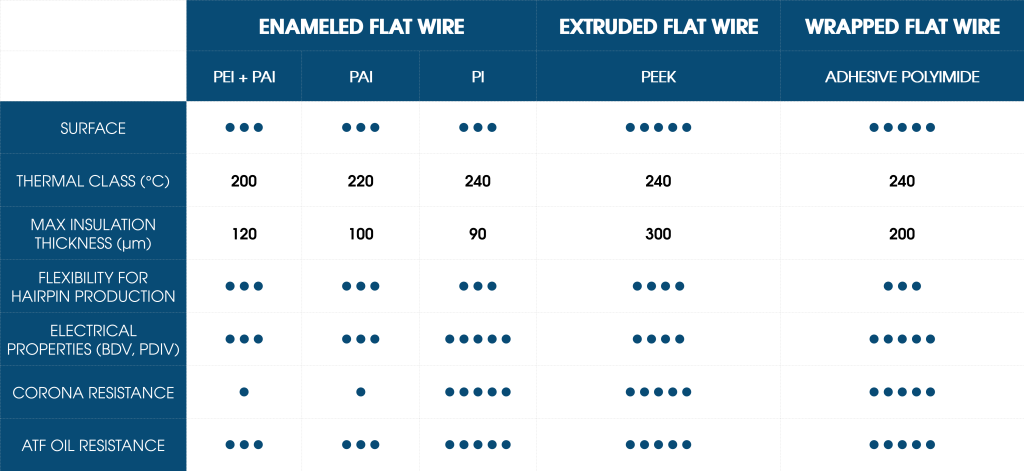

Extruded PEEK Flat wires: For a slightly higher investment, extruded PEEK flat wire emerge as the excellent product to respond to the high performance required by the E-mobility sector. With a high thermal class, impeccable partial discharge resistance and exceptional compatibility with oils, these flat wires not only meet high quality standards, but also play a crucial role in sustainability, significantly contributing to the reduction of solvent emissions.

PAI and PI Enameled Flat Wires: In the vast panorama of enameled flat wires, PAI (polyamide-imide) presents itself as a choice which, while maintaining a lower insulation thickness than PEEK, retains notable electrical and compatibility properties at a more accessible cost. PAI, still widely used in standard electric motors, stands out for its ease of application and competitive price. We also offer a valid alternative to PEEK: PI (polymide), characterized by comparable performance in terms of thermal class (240) and compatibility with oils. The flexibility of PI, thanks to its thermosetting nature, surpasses that of PEEK, ensuring a complete solution for the changing needs of the continuously evolving electrical sector.

Wrapped Adhesive Polyimide Flat Wires: We recognize that there may be hesitancy on the part of OEMs towards a taped solution, however our taped adhesive Polyimide flat wires represent one of the products with the highest PDIV, comparable to PEEK. Furthermore, the compatibility with cooling oils is optimal. This distinctive approach is made possible thanks to the use of a specific glue that ensures adhesion and seal.

Litz Wire: The Litz Wire solution offers high design flexibility and performance at high frequencies, meeting the most advanced and specific needs of electric vehicle manufacturers.

This detailed comparison provides a comprehensive overview of the distinctive features of each solution, facilitating informed decision making for specific applications in the context of E-mobility.