Introduction

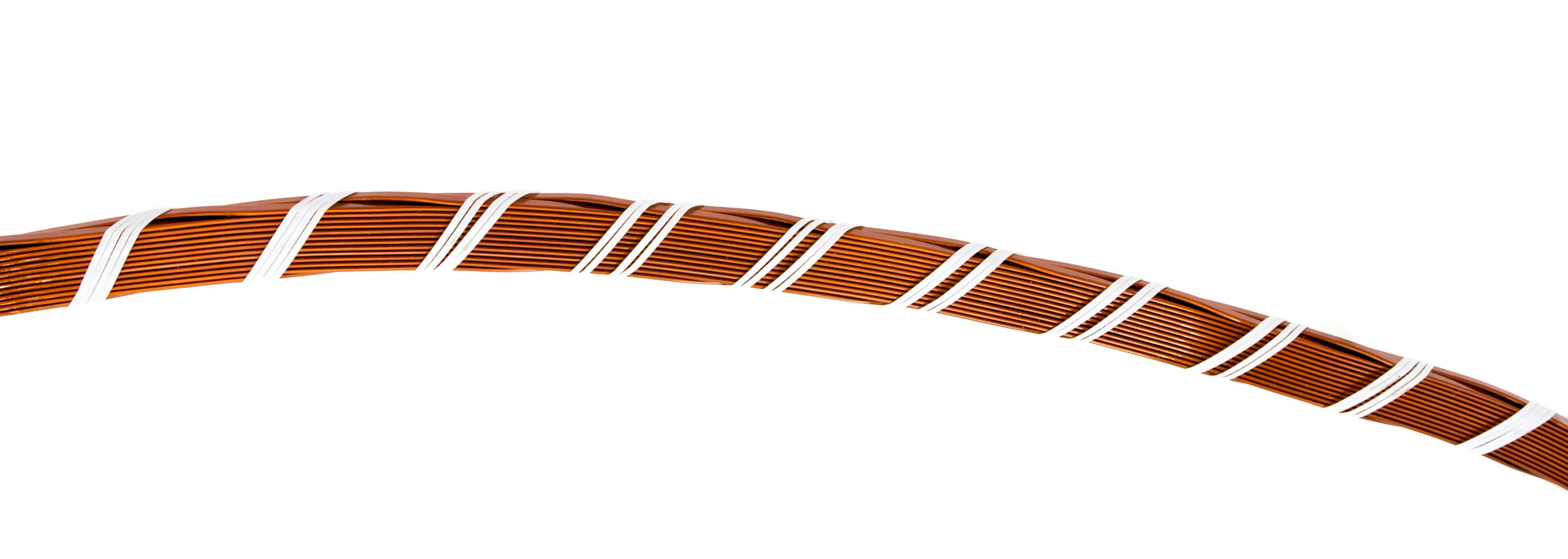

Today’s trend is to seek maximum efficiency at sustainable costs for power transformers. That’s why Low Thickness Enamel technology (LTE) is created for more compact CTCs and more efficient transformers.

Engineering

Reducing the size of the elementary conductors, thus increasing their overall number, is one of the most common methods to reduce losses given by eddy currents, increasing the filling factor.

LTE technology allows to reduce the thickness of the enamel of each strip, without affecting the performance of the electrical insulation. With LTE technology it is possible to apply enamel with a minimum thickness of up to 0.06 mm. The application of the enamel has been studied and obtained through specifically designed tools, allowing a smooth distribution without inaccuracies in every point of the conductor.

Advantages

The adoption of LTE technology allows to maintain high thermal conduction of the CTC, reducing the electrical resistivity of the whole winding.

The CTC LTE also allows to obtain higher filling factors and reduce the overall dimensions of the winding.

Download

Low Thickness enamel CTC vertical_align_bottomDownload PDF