Home » Products » Oxidized litz wire

Bare conductors

Conductors for automotive

Oxidized litz wire

Oxidized Litz Wire maximizes the efficiency of the final product with increased copper usage and a reduced environmental footprint. Its solvent-free production process makes it a sustainable choice for modern and demanding applications

Introduction

The oxidized Litz Wire is an innovative solution proposed by De Angeli Prodotti designed to maximize the efficiency of the final product. This technology allows for a significant increase in the use of copper in winding, while ensuring reduced environmental impact. A distinctive feature of the oxidized Litz Wire is its production process, which completely eliminates solvent emissions, making it a sustainable choice for modern and more demanding applications.

Engineering

The oxidized Litz Wire takes the fundamental concept of litz cables, where electrical insulation is provided by the tape wrapped around the conductor rather than between individual wires, to its extreme consequences.

In this innovative design approach, the oxidized Litz Wire pushes beyond traditional limits by significantly reducing the thickness of the insulation on each individual wire. This reduction results in an oxide layer in the insulation of the single wire that is up to ten times thinner than standard Grade 1 enamel, greatly increasing the fill factor.

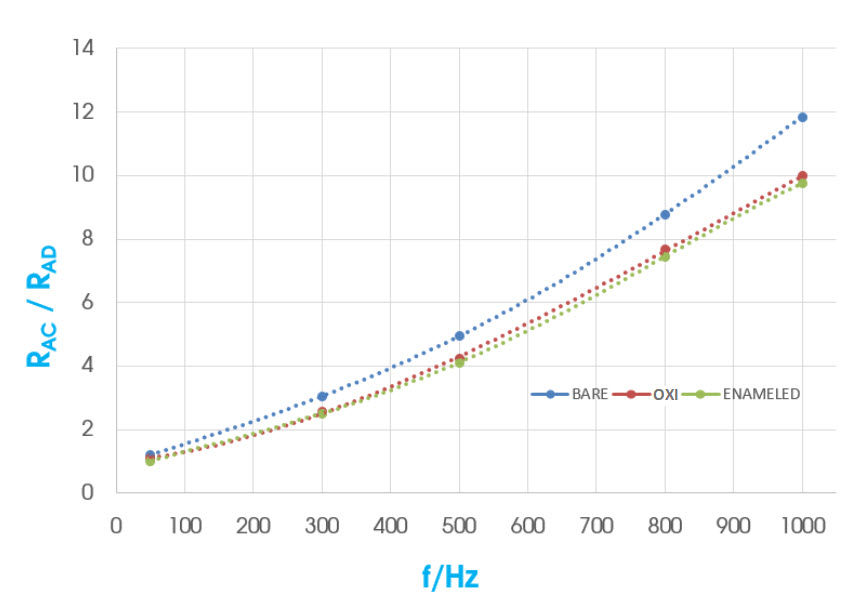

From the above graph, three different configurations of Litz are compared: enamel-coated Litz, bare Litz, and oxidized Litz. As observed, even in the case of oxidized Litz, an increase in frequency corresponds to an increase in AC resistance.

| Individual wire | Material | Spec. Resistance [Ωmm2/m] | Density [Kg/m3] | Diameter [mm] |

| Copper | 0.0171 | 8890 | ≥ 0.20 | |

| External insulation type | Type | Thickness [µm] | ||

| Polyester | 23 | |||

| Nomex T410 | 50 | |||

| Polyimide | 25 – 38 – 50 | |||

| Conductofol | 90 | |||

| Mica-Glass | 100 | |||

| And much more! | – | |||

Advantages

In summary, oxidized Litz Wire offers several significant advantages. Its advanced design enables an increase in overall system efficiency due to the larger bare copper section and reduced losses, with a considerable increase in fill factor. Additionally, its sustainable nature, stemming from solvent-free production, makes it an ideal choice for companies committed to reducing the environmental impact of their operations.

Image Gallery

Download

Oxidized Litz Wire vertical_align_bottomDownload PDF