De Angeli Prodotti: we’re “only” 30 years old — celebrated with the 30th Anniversary Open Day in Bagnoli di Sopra.

In an era marked by global challenges, there are companies that prove growth is possible. De Angeli Prodotti celebrates 30 years not as a rare milestone, but as proof that a clear vision — built on innovation, a commitment to the green economy, and respect for the entire social value chain — can become shared value. In the Province of Padua, in Bagnoli di Sopra, De Angeli Prodotti celebrated a human-centered business culture in which all production takes place in Italy and technological innovation is the result of constant investment in research. The celebrations took the form of an Open Day that involved customers and suppliers, as well as employees and their families, institutions, and the entire local community, with the goal of showcasing the capabilities and potential of the authentic Italian industrial spirit.

Summary:

- 1. The President letter and the company’s “why”

- 2. From an essential range to high-tech portfolios

- 3. Industrial growth and an “open factory”

- 4. A culture that works as a system

- 5. The near future: servitization and smart grids

- 6. Here, where the future is born

- 7. From reporting to perspective

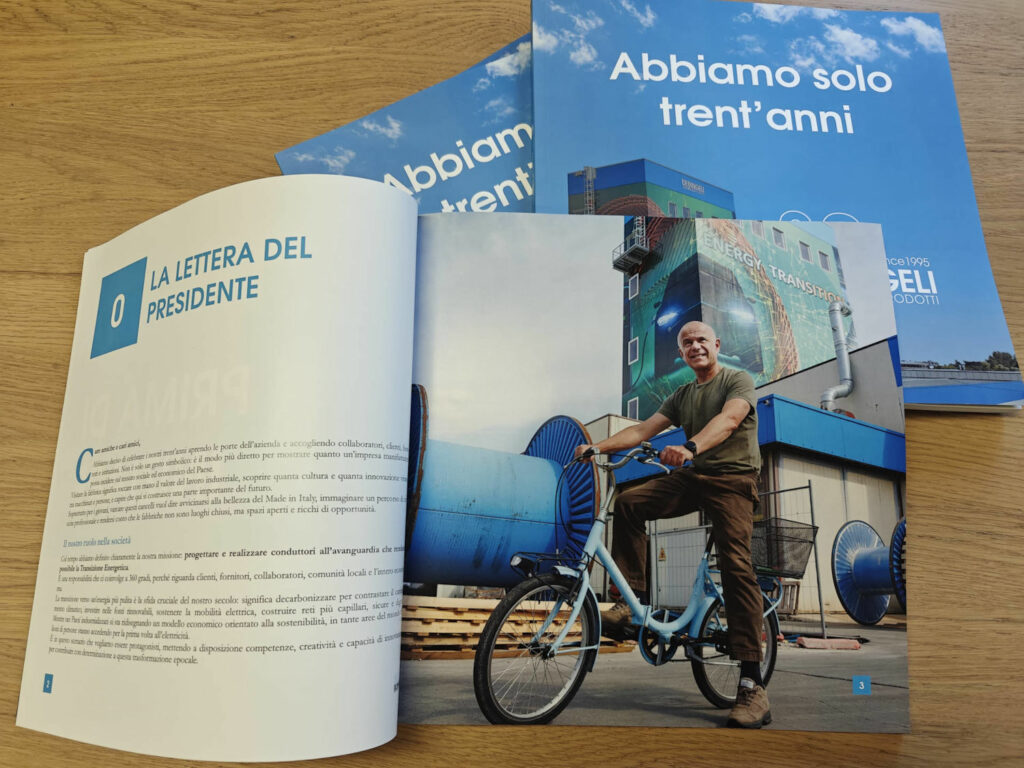

1. The president’s letter and the company’s “why”

In the commemorative volume released for the anniversary, president Luca Mora clearly sets out the mission: “to design and manufacture cutting-edge conductors that enable the Energy Transition”, taking responsibility toward customers, suppliers, employees, and local communities. The decision to grow in Italy — investing in R&D, facilities, and training — goes hand in hand with a management model based on trust, accountability, and continuous improvement, with safety as the first daily commitment.

This vision translates into a “shared mindset” that blends practical philosophy, lean management, and structured problem solving, turning events and issues into lessons learned and operational standards. It’s a way of working that aims to “see early, dare wisely, make it real”, nurturing a culture that rises from the shop floor all the way to shaping industry technical standards.

2. From an essential range to high-tech portfolios

In the beginning, in 1995, De Angeli’s production focused on a few conductors for high-voltage lines and on round enameled wire/taped flat wire. Today the company offers “the broadest range on the market”, spanning from High-Tech Magnet Wires for e-mobility electric machines to overhead line conductors, with proprietary developments in materials, insulation, and processes.

One milestone came in 2002 with the launch of CTC (Continuously Transposed Cable), a key technology for power transformers. CTCs are bundles of rectangular enameled wires transposed so that each conductor repeatedly occupies every internal position — a solution that increases the transformer’s electromagnetic efficiency. This specialization is also evidenced by the technical datasheets and process brochures published by the company.

In 2010 came conductors with fiberglass insulation and glass–polyester composites (Daglas) for high-power motors, wind turbines, and critical installations, offering greater mechanical strength, thermal stability, and dielectric safety.

In 2014, colored conductors made their debut: an eco-friendly, solvent-free coating that improves landscape integration (with the first installations in Austria) and, thanks to high emissivity (up to 0.8), increases ampacity while reducing losses. In the same year, the company completed the La Spezia–Vignole project, using a high-temperature aluminum-alloy conductor (Ø49 mm) that delivered +50% capacity and −26% losses at a critical node of the national grid.

From 2017 onward, developments on Anti-Ice conductors with super-hydrophobic treatments were consolidated to limit ice sleeves and outages — a technology later adopted across Northern Europe as well; the company has documented adoption and use cases on its technical portal.

In 2019 came major contracts for conductors with a carbon-fiber core (stemming from the ACCM patent filed in 2006), and the company expanded its expertise in polyimide/Kapton paired with FEP for high-temperature insulation (>200 °C), enabling more compact and efficient motors.

In 2020, the Litz department was established (conductors made of hundreds/thousands of ultra-fine strands, down to 0.05 mm) for high-frequency applications, from charging stations to urban rail traction.

In 2021, the company built for Statnett a special 380 kV conductor that crosses the Norwegian fjords; machines, floors, and buildings were modified to handle reels 3,750 mm in diameter and up to 45 tons— a “record-breaking” project also destined for the world’s longest span. In the same year, De Angeli Prodotti entered the automotive sector with dedicated lines and materials such as PAI, PI, and PEEK, serving hairpin stators, rotors, and cooling systems for electric vehicles.

3. Industrial growth and an “open factory”

Growth has been gradual but steady: from the ambitious dreams of 1995 to €300 million in revenue in 2025; in parallel, the plant has expanded from 43,000 m² to 102,500 m², with four new departments and a “tower” symbolizing technological ambition, as well as a photovoltaic plan now extended to all roofs (from 2,300 to 4,200 panels for a total of 2,750,000 kWh/year). The avoided environmental impact is compared to 900 trees per year — 18,000 trees over 20 years.

The structural entry of women into production marked another important milestone: from 2 colleagues out of 331 (0.6%) pre-2022 to 85 out of 467 (18.2%) in September 2025, with a strong emphasis on training the new generations and transferring know-how from veterans to younger staff.

4. A culture that works as a system

The push toward high–thermal-capacity conductors and advanced insulation addresses structural trends: widespread electrification, non-dispatchable renewables, and grids that are heavier and more interconnected. In this context, materials, transposition geometries (CTC), surface treatments (Anti-Ice, high emissivity), and digitalization (Smart Conductor) are levers to boost reliability and performance without sacrificing maintainability. It’s “useful” innovation — field-driven and codified into standards and processes.

Beyond the work of optimizing our products, we believe in a culture that weaves together pragmatism, phenomenology, and “charitable interpretation”: tools to truly listen, decide better, and turn every problem into shared learning. This cultural toolkit is not rhetorical window dressing: it translates into organizational choices (delegation, anti-bureaucracy, mixed problem-solving teams) and into an investment timeline aligned with the real demand of our value chains.

5. The near future: servitization and smart grids

If there’s one lesson from these thirty years, it’s the importance of the relationship with customers as a lever for innovation. Co-designing solutions, fine-tuning specifications, testing new composites and insulation systems, and qualifying processes to meet increasingly demanding standards transforms a simple supplier into a strategic technology partner. This enables the entire value chain — from raw materials to transformers — to make significant leaps in efficiency and reliability.

Looking ahead, De Angeli Prodotti points to three directions: network digitalization (Smart Conductor), servitization (value-added services across the conductor’s lifecycle), and capable young professionals already “at the controls”. The schedule of international events (Coiltech Germany/USA) confirms its outward focus and ongoing dialogue with OEMs and utilities.

6. Here, where the future is born

During the event, guests were able to visit every department of the factory — from the dojo to the museum, via the enameling, drawing, stranding, and taping lines — and see firsthand the products driving the energy transition and the people who make it all possible.

Thirty years are a measure of reliability. But they’re also a starting point for tackling the curve of change ahead for the electrotechnical sector: more complex supply chains, stricter environmental and social standards, digitization of production and quality-control processes, and global competition on costs and know-how. The decision to grow headcount and to focus on higher–value-added technological segments points to a clear course: safeguard quality, invest in people, and pursue efficiency at scale without offshoring the heart of manufacturing.

7. From reporting to perspective

The thirtieth-anniversary celebration, covered by the local press, gave voice to the industrial project: innovation, strong local roots, and an international outlook. The local daily La Piazza Web reported the presence of institutional figures (Regional Council President Enoch Soranzo; regional councilors Elisa Venturini and Fabrizio Boron; Forza Italia Veneto chairman Flavio Tosi; Monselice mayor Giorgia Bedin; and several mayors from the Bassa Padovana area, including Massimo Cavazzana) and captured the event’s atmosphere, while a video piece collected remarks from Chairman Mora, providing further public context for the occasion.

This birthday has the feel of major anniversaries that don’t close chapters but open new ones. Thirty years ago, in 1995, De Angeli Prodotti was born with the ambition to innovate in a highly technical field. Today, with two sites between Italy and France, a growing workforce, and a pipeline of advanced products and materials, the company confirms its role in supporting the transformation of Europe’s power grids and electrical equipment. And it does so by renewing a pact of trust with its workers, industrial partners, and the surrounding community. If the first thirty years were the time of building, the next will be the time of scaling — industrial and international… yet always Made in Italy.