Home » Products » ACSR conductor (Aluminum Conductor Steel Reinforced) / ACSR-AW

Standard conductors

ACSR conductor (Aluminum Conductor Steel Reinforced) / ACSR-AW

ACSR conductor is the type of conductor most used worldwide and it is composed of a steel core and one or more hard drawn aluminum layers.

Introduction

It’s the type of conductor most used worldwide and it is composed of a steel core and one or more hard drawn aluminum layers.

But what’s the ACRS meaning? The steel core, that is the mechanical support, can be composed of galvanized steel wires or Aluminum Clad Steel wires (ACS).

The wires of the conductive layers could be made of hard drawn aluminum or of thermal aluminum alloy and they have a rounded section.

Engineering

Even if the ACSR wire and ACSR-AW conductors are listed in the international norms, as EN 50182, De Angeli Prodotti can realize every customized composition.

Specifically for the conductive layers in aluminum or aluminum alloy, De Angeli Prodotti proposes alternative shapes as trapezoidal wires, “Z” wires, etc.

Advantages

The use of trapezoidal or “Z” wires allows a substantial raise of the filling-factor. Consequently, considering the same external diameter, the conductive section and the capability of energy transport increase remarkably. In addition, thanks to extremely flat surface, the drag coefficient (CX) decreases.

The use of ACS (Aluminum Clad Steel) wires as the core guarantees an ultimate resistance to the corrosion, especially in saline environments.

In the case of zinc coated wires, the use of grease provides an adequate protection.

The use of ACS (Aluminum Clad Steel) wires as the core guarantees an ultimate resistance to corrosion, especially in saline environments, making ACSR (Aluminum Conductor Steel Reinforced) conductors highly suitable for overhead power transmission. By incorporating trapezoidal or “Z” wires, ACSR cable substantially increase the filling-factor, resulting in a significant enhancement of the conductive section and energy transport capability within the same external diameter.

This design improvement leads to a remarkable improvement in efficiency and performance, particularly in extra high voltage applications. Additionally, the extremely flat surface of ACSR conductors contributes to a reduced drag coefficient (CX), further optimizing their aerodynamic properties and minimizing energy losses during transmission. Moreover, in cases where zinc-coated wires are utilized, the application of grease provides adequate protection, ensuring prolonged durability and reliability even in harsh operating conditions. In essence, ACSR conductors represent a robust and versatile solution for overhead power transmission, offering enhanced performance, longevity, and resilience in demanding environments.

Download

ACSR - Conductor data sheet vertical_align_bottomDownload PDF

Case Study

-

-

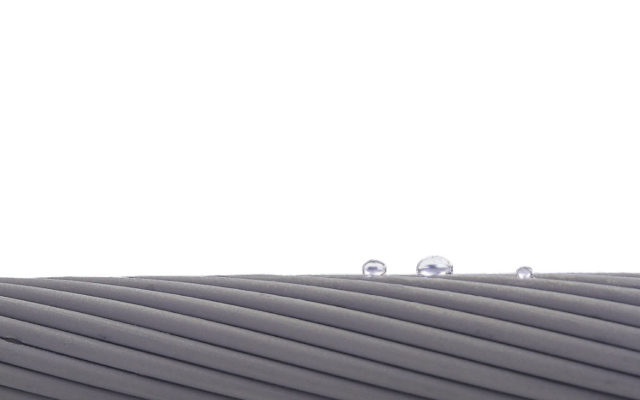

A new transmission line of 380 kV built to bring more energy in the Stavanger area (Norway)

The project consists in a new transmission line of 380 kV built to bring more energy in the Stavanger area due to the increase of the consumes linked to the increase of the population in the city. The customer invited De Angeli Prodotti to participate to the tender because they needed special, resilient and high quality conductor to cross the 2,7 km long fjord. A conductor of Aluminum Alloy and Steel was designed and produced in our plant in Italy, one of the biggest ACSR ever produced in the factory with a diameter of 56,7 mm and a weight of 6,40 kg/m. To reduce the corona noise and the shining effect of the aluminum wires, we proposed a sandblasted conductor. The process of sandblasting is made internally in a special machine that, through some guns, sprays a specific sand on the conductor to reach a rough and clean external surface.