Introduction

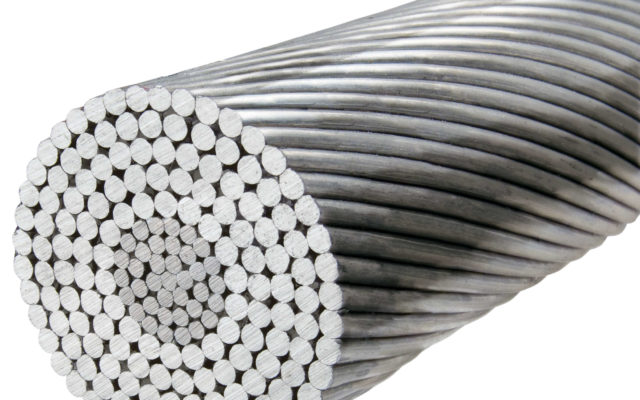

It is a monometallic conductor composed of an alloy AlMgSi (series 600).

The AAAC conductors are largely used in France where De Angeli Prodotti has a lot of experience in the production of these conductors.

Engineering

The aluminum alloy series 6000 can be produced in more combinations to highlight the electrical part compared to the mechanical part and vice versa.

The AAAC are regulated by international norms as EN 50182 and in addition De Angeli Prodotti can realize every customized composition.

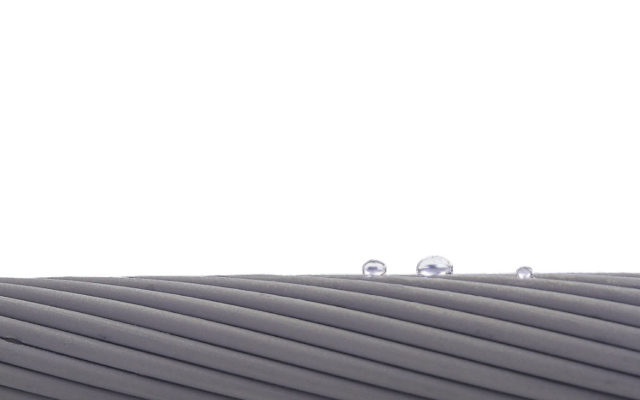

De Angeli Prodotti proposes alternative shapes as trapezoidal wires, “Z” wires, etc. for all the aluminum wires.

Advantages

The AAAC conductors guarantees a good ratio of electrical conductivity to mechanical resistance, so they can be installed in medium and long spans.

The alloys series 6000 offer excellent corrosion resistance performance.

The AAAC conductors offered by De Angeli Prodotti stand out as versatile and reliable solutions for a wide range of transmission and distribution line applications. Their composition, featuring the AlMgSi alloy from the series 6000, ensures excellent corrosion resistance and durability, making them suitable for installation in various environmental conditions. Moreover, De Angeli Prodotti’s expertise in producing customized compositions enables tailored solutions to meet specific project requirements, enhancing flexibility and adaptability.

Furthermore, the AAAC conductors exhibit a commendable balance between electrical conductivity and mechanical strength, thanks to their design and alloy composition. This optimal ratio makes them well-suited for medium and long spans, contributing to the efficient and reliable operation of transmission and distribution lines. Their ability to maintain sag characteristics, even under extra high voltage conditions, ensures consistent performance over extended periods.

Additionally, the availability of alternative shapes such as trapezoidal and “Z” wires underscores De Angeli Prodotti’s commitment to innovation and meeting diverse industry needs. Whether it’s for AAC, AAAC, or ACSR conductors, the company’s offerings excel in terms of strength-to-weight ratio, providing durable and efficient solutions for overhead transmission and distribution networks. Overall, De Angeli Prodotti’s AAAC conductors play a crucial role in enhancing the performance and reliability of modern transmission infrastructure, driving progress and connectivity in the energy sector.

Download

AAAC - Conductor data sheet vertical_align_bottomDownload PDF