Introduction

Fiber-in-Metal Tube (FIMT) combines durability and versatility, offering reliable protection for optical fibers in harsh environments. Perfect for data transmission and communications, FIMTs ensure long-lasting performance even under mechanical stress and harsh conditions.

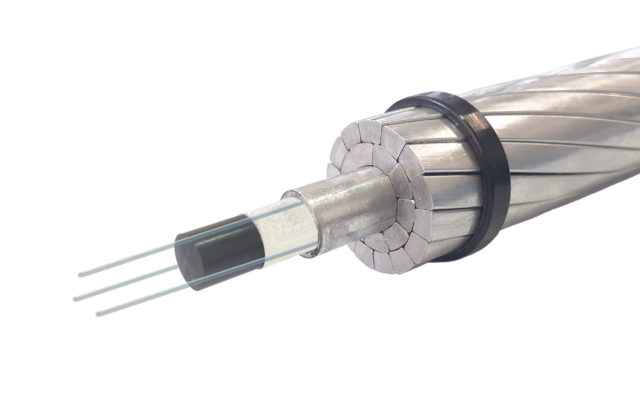

Their compact, all-metal design makes them the ideal choice for integration into OPGW and OPPC cables, enabling the deployment of high-density fibers without compromising strength or stability.

Today, FIMTs are opening up new opportunities in smart infrastructures and are also being used as advanced sensors inside conductors, underground cables, and submarine cables. They enable precise monitoring of temperature, strain, and other key parameters, supporting both communications networks and smart power grids.

Engineering

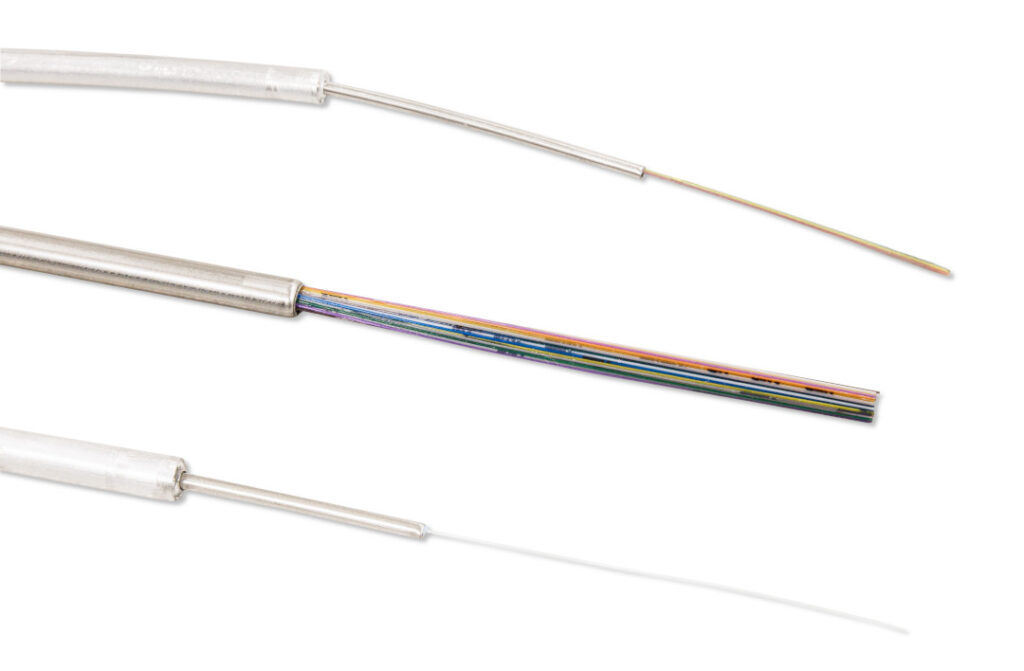

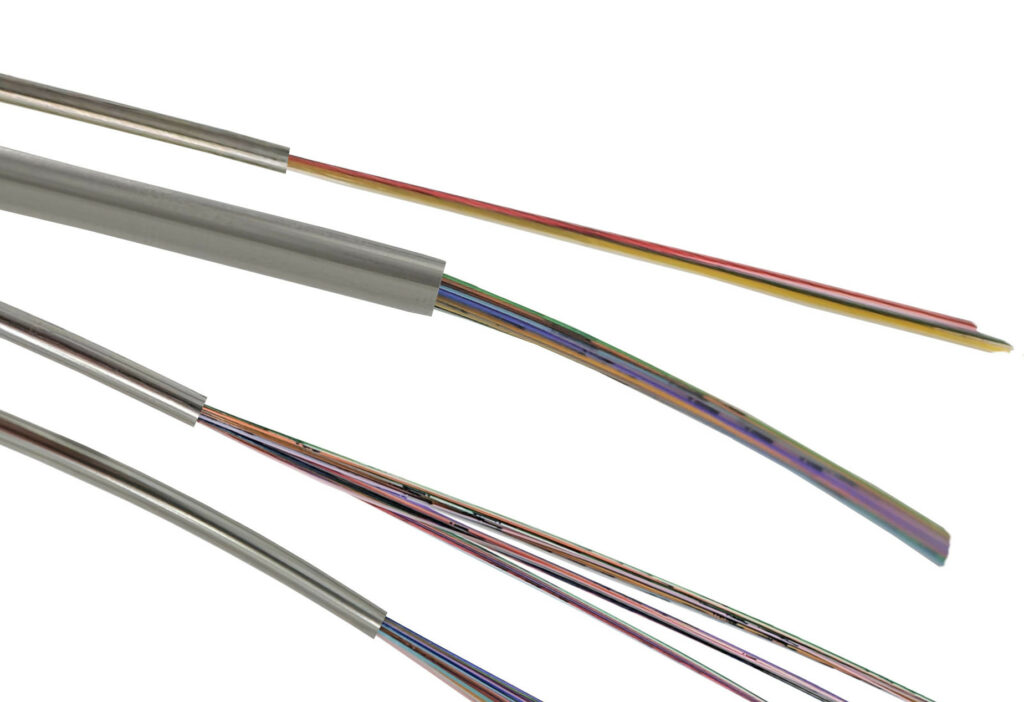

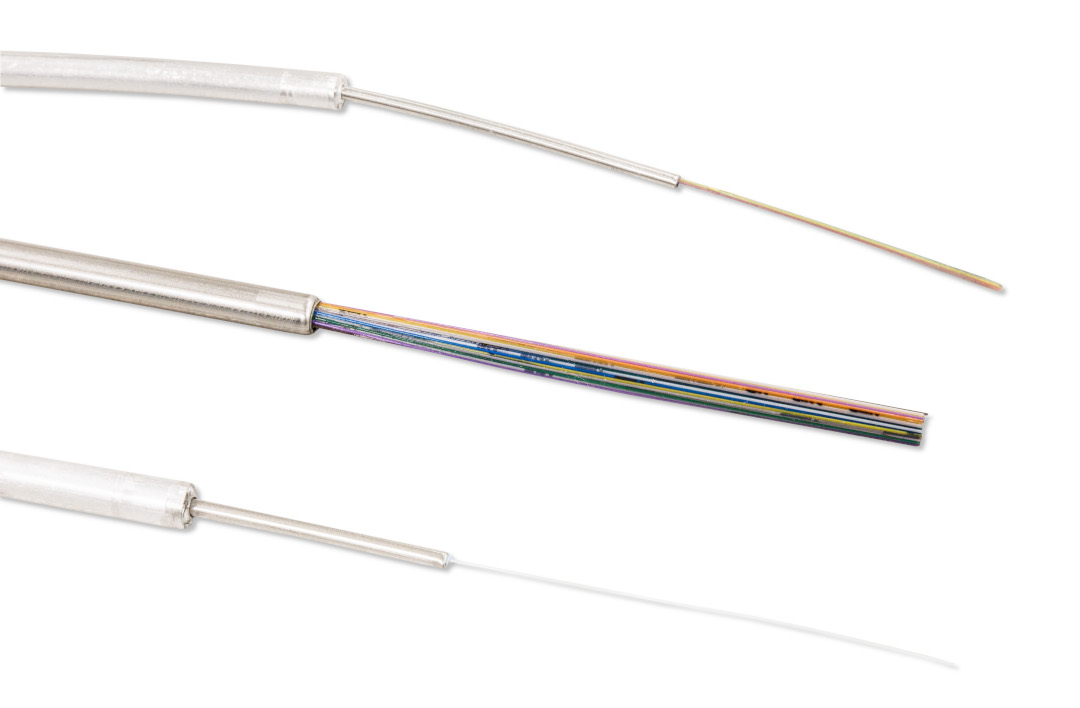

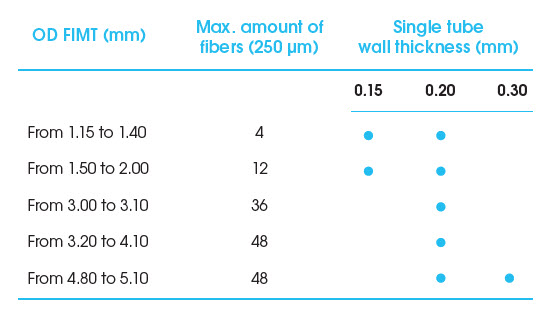

We provide a wide range of FIMT configurations and sizes, tailored to meet the specific requirements of the final application. Possible variants include different tube diameters, fiber number, and tube materials, available in stainless steel or stainless steel with aluminum coating.

Fully compatible with all major single-mode and multi-mode fibers, including G.652D, G.655, G.657A1 and more, our FIMTs offer maximum flexibility to match your network design and performance needs.

The heart of FIMT technology lies in the ability to integrate optical fibers within a continuous, watertight metal cladding.

- The metal tube: typically made of stainless steel or corrosion-resistant superalloys, it acts as an impenetrable barrier against hydrogen, moisture, and chemicals.

- Optical fibers: the tube can contain one or multiple fibers (e.g., G.652D, G.655, G.657A1), immersed in a special gel that dampens vibrations and prevents longitudinal water penetration.

- Customization: De Angeli Prodotti offers customized solutions, calibrating the tube diameter, wall thickness, and alloy type based on the mechanical and thermal stresses of the specific project.

Advantages

The special conformation of FIMT allows for excellent performance compared to traditional polymer protection systems:

-

Superior mechanical protection: extreme resistance to crushing, traction, and impact, essential during installation and operational life.

-

Reliability over time: the metal coating guarantees a useful life of more than 40 years, protecting the fibers from aging induced by external agents.

-

Real-Time Monitoring: integrated in the Smart Conductor, FIMTs allow distributed monitoring of temperature (DTR) and line deformations.

-

Thermal resistance: ability to operate over a very wide temperature range while maintaining optical properties unchanged.

-

Application versatility: ideal for high-voltage underwater, underground, and overhead installations.

Image Gallery

Download

FIMT - Fibers in Metal Tube vertical_align_bottomDownload PDF