Home » Products » ACSS conductors (Aluminum Conductors Steel Supported)

HTLS conductors

ACSS conductors (Aluminum Conductors Steel Supported)

ACCS wire is particularly suitable for replacing AAAC conductors, its core is composed of high-strength zinc-aluminum steel wires.

Introduction

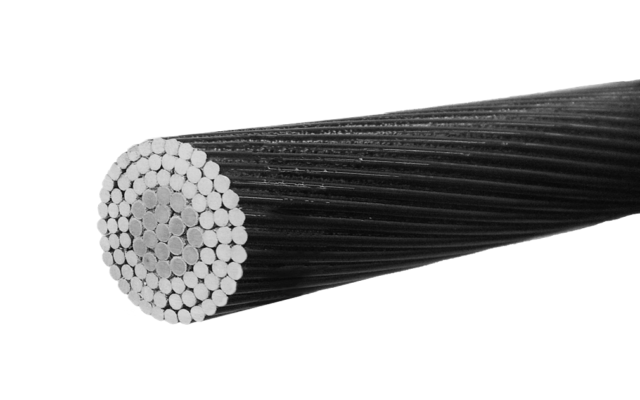

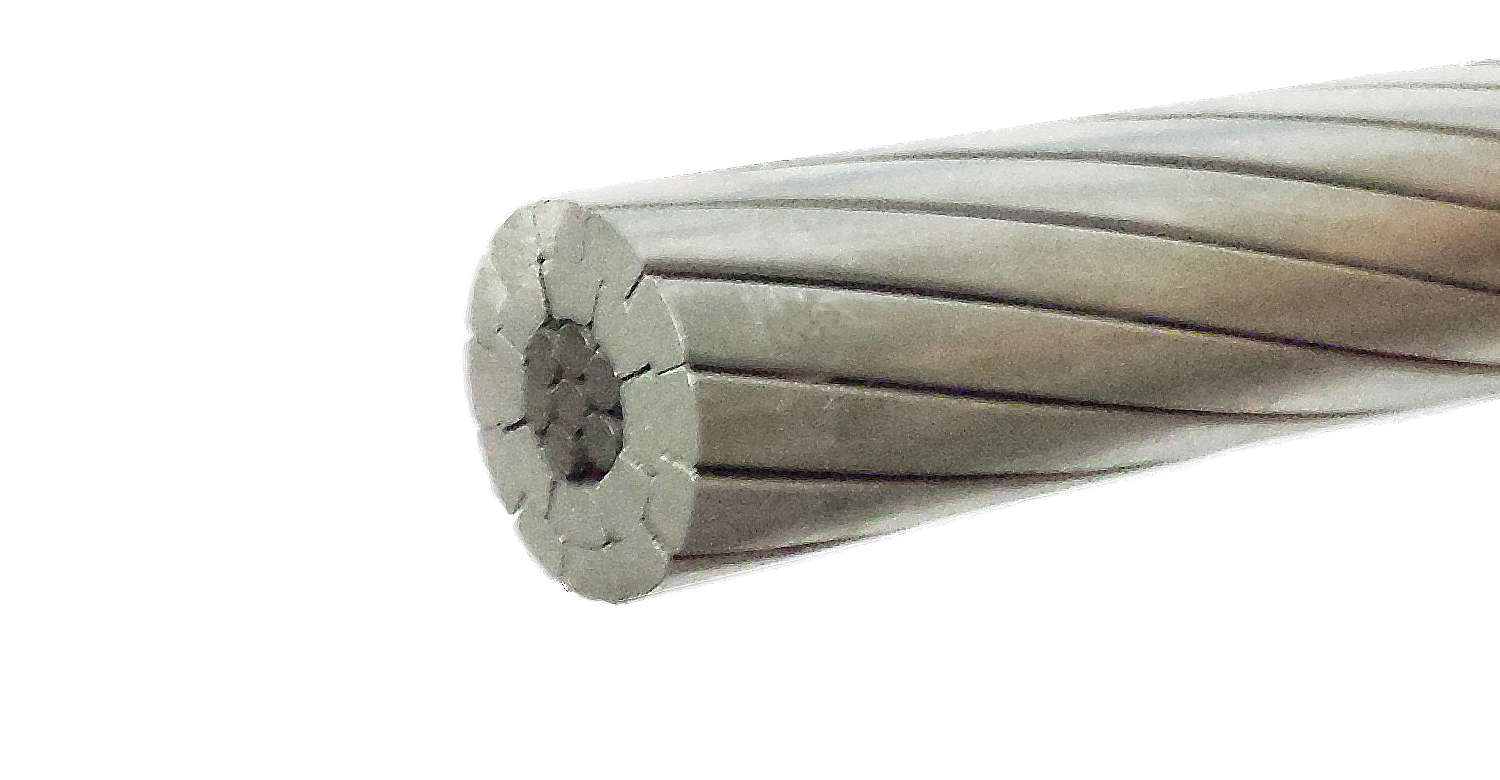

ACSS (Aluminum Conductor Steel Supported) is particularly suitable for the replacement of AAAC (All Aluminum Alloy Conductor) conductors: its core is made of UHTS (Ultra High Tensile Strenght) steel wires protected by a coat of zinc-aluminum and the conductive layers are in annealed aluminum.

ACSS (Aluminum Conductor Steel Supported) is particularly suitable for the replacement of AAAC (All Aluminum Alloy Conductor) conductors due to its robust construction and enhanced performance capabilities. Its core is comprised of Ultra High Tensile Strength (UHTS) steel wires, which are encased in a protective coating of zinc-aluminum alloy. This design ensures exceptional durability and resistance to various environmental factors. Moreover, the conductive layers of ACSS consist of annealed aluminum, facilitating efficient electricity transmission while minimizing energy losses.

De Angeli Prodotti, a leading manufacturer in the energy sector, has played a pivotal role in advancing the deployment of ACSS technology. With a proven track record of excellence, De Angeli Prodotti has successfully produced and supplied over 1,000 kilometers of ACSS wires to support diverse infrastructure projects worldwide. Through their commitment to innovation and quality craftsmanship, De Angeli Prodotti continues to elevate industry standards and contribute to the modernization of electrical grids.

Furthermore, the widespread adoption of ACSS conductors underscores the industry’s recognition of its numerous benefits. Beyond its superior mechanical strength and corrosion resistance, ACSS offers enhanced ampacity, allowing for greater power transmission efficiency over long distances. This increased capacity is particularly advantageous in regions experiencing high demand or facing challenges such as voltage drops and line congestion. Additionally, ACSS conductor facilitate ease of installation and maintenance, further reducing operational costs and downtime for utilities and grid operators. As energy networks evolve to meet the demands of a rapidly changing world, ACSS technology stands poised to play a pivotal role in ensuring the reliability and sustainability of power infrastructure.

Engineering

The zinc coat for the protection of steel from corrosion contains 5% of aluminum, which contributes to the reduction of the overall electrical resistance of the conductor.

The annealing of the conductive layers improves the electrical conductivity characteristics of the aluminum.

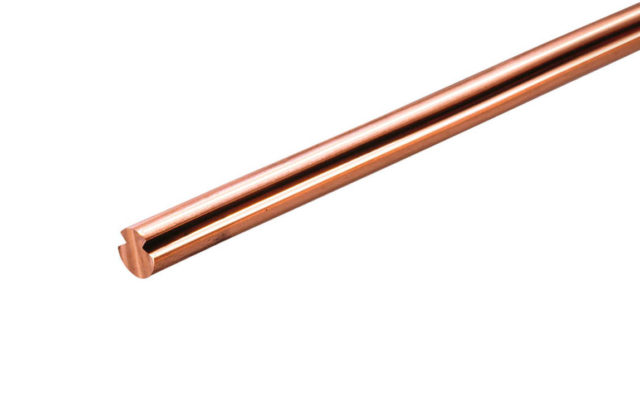

For the annealed external conductive layers, De Angeli Prodotti offers alternative shapes such as trapezoidal wires, “z” wires, etc.

Advantages

The combination of UHTS (Ultra High Tensile Strength) steel wires with the annealed aluminum conductive layers results in a reduction of the transition point (Low Knee-Point), increases the current flow rate (Ampacity +100%) and allows a reduction of line losses.