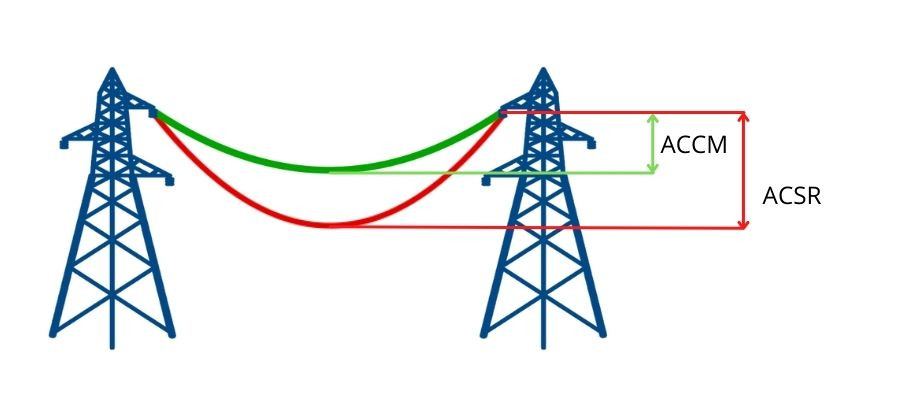

Thanks to our ACCM power line in the north-est of Italy was upgraded and achieved the aim to increase ampacity and reduce the sag.

At the end of June 2021, a line in the north-est of Italy was the target of an upgrade campaign. The aim the increase of ampacity and the reduction of the sag.

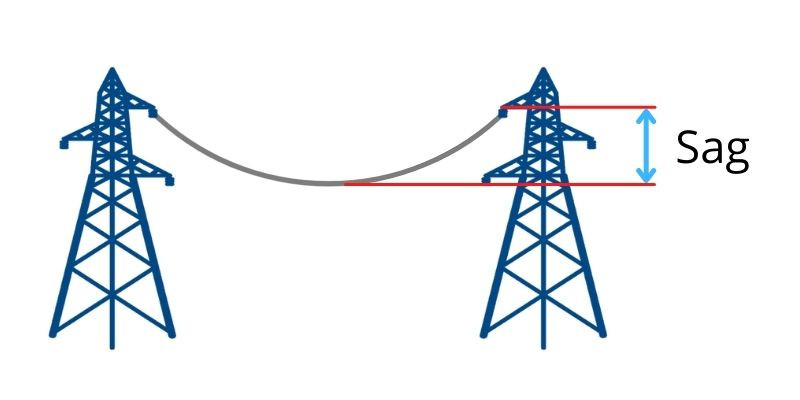

What is sag in overhead power lines?

The “sag” is a geometric term that refers to the height of an arch (in this case, the one that forms a taut cable). In practical terms it indicates how much the cable “hangs” (due to its own weight) with respect to the straight line.

What are the benefits of sag reduction in power lines?

One of the benefit of the sag reduction is the lowering of the electromagnetic field measured at the ground level. Especially in the last years, the electromagnetic field values play a key role in the design and also on the usability of the telecommunication and transmission infrastructures. Not only infrastructures like antennas or other radio-frequencies systems are interested by this aspect.

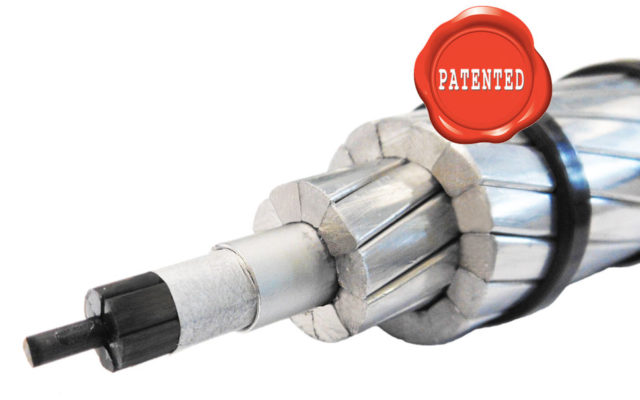

To solve these type of problems, De Angeli Prodotti developed a very lightweight conductor. In it the structural function is done by a carbon fiber composite core instead of the more traditional stainless steel or aluminium clad steel. A multi-stranded carbon core made up by 7 wires was use to give flexibility and strength at the same time. De Angeli Prodotti named “ACCM” this type of conductor.

The big drop in weight of the conductor itself allowed the increase of ground clearance (i.e. the distance between the phase and the ground) so a significant reduction of the electromagnetic field detected was guarantee.

A big success of the ACCM project for an important power line

This line is almost 30km long, over 250km of conductor, divided into 102 reels, were produced in our factory to equip the entire line. Due to the importance and also to the very high grade of innovation of this project, training sessions to form the installation companies were done by our R&D department. Our team of R&D department were also involved during the installation procedures on the field.

The stranding process of the last of the 102 reels was done few weeks ago and it was made possible by an excellent job performed inside our factory and also on the field. This success of the ACCM project will allow the line to work at its best for future years.