Some materials, such as polymers, exhibit viscoelastic behaviour; that is, they show both elastic properties (like an ideal spring) and viscous properties (like an ideal damper).

Dynamic Mechanical Analysis (DMA) measures the viscoelastic properties of most polymeric and composite materials during a programme of increasing temperature and constant or variable frequency. DMA is used to detect the Glass Transition Temperature (Tg), at which the material changes from purely elastic to viscoelastic behaviour.

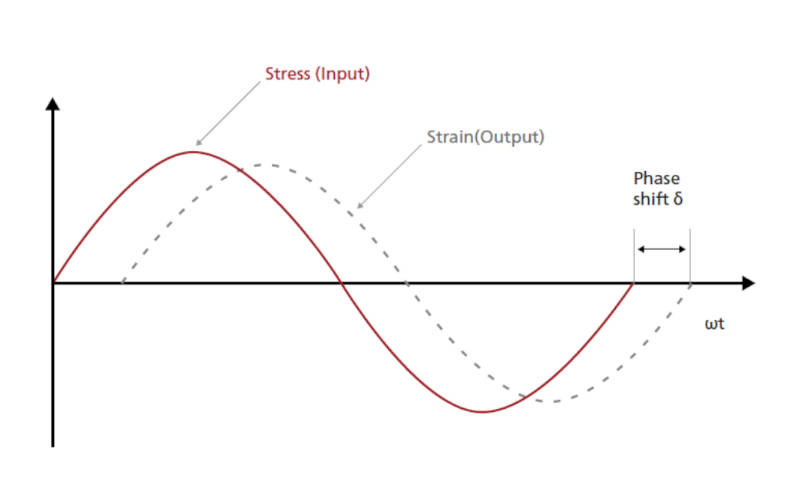

To perform the test, the sample (Input) is placed inside a climatic chamber, allowing it to be heated. A sinusoidal force (Stress) is then applied, which results in a sinusoidal deformation (Strain) of the sample itself (Output).

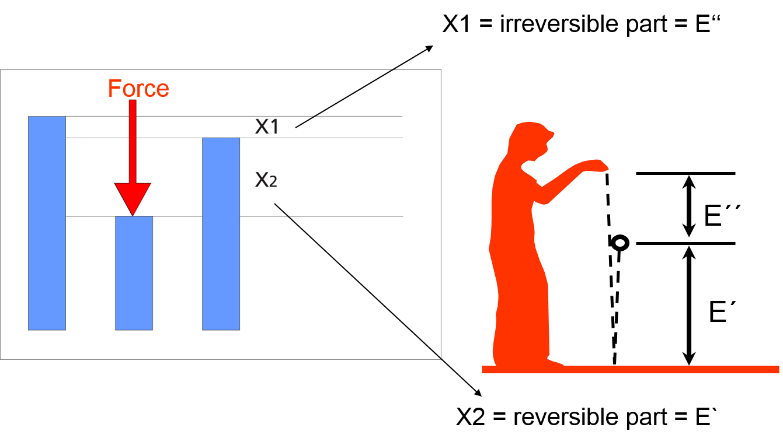

The elastic response is described by the E’ modulus (Storage Modulus), considered “in-phase with the stress,” which is usually represented on a graph.

The viscous response is described by the E” modulus (Loss Modulus), which is “out-of-phase with the stress.” The delay, shown in the dashed curve (Figure 1) and indicated as “Phase shift d” increases with temperature. It is a measurement associated with the oscillation energy transformed into heat and is, therefore, irrecoverable.

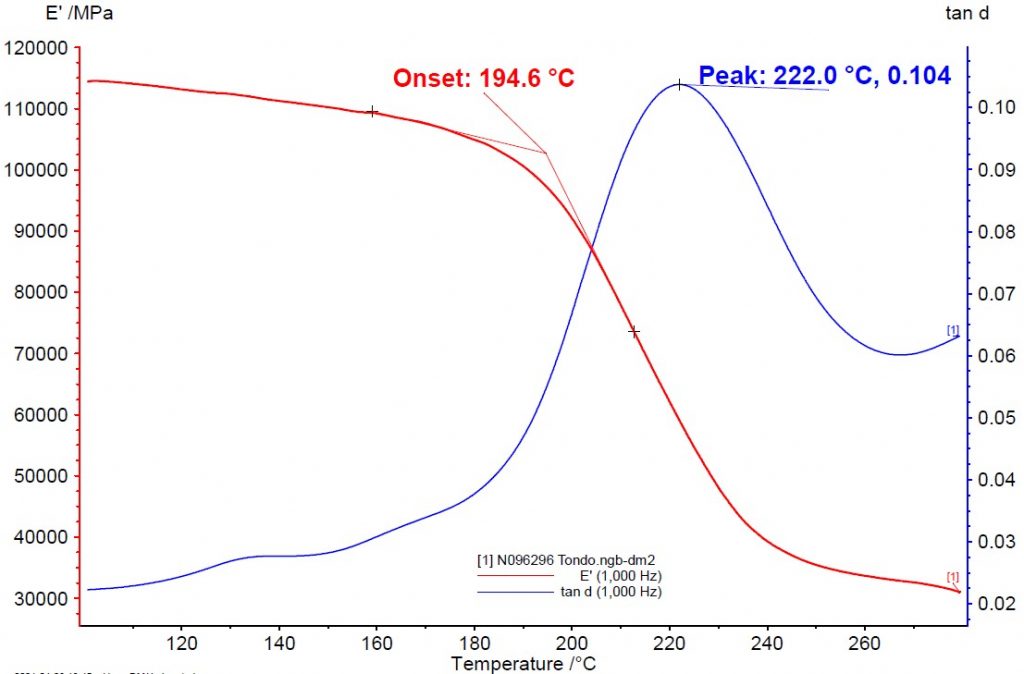

The software connected to the instrument generates two curves:

- In red: This curve identifies the behaviour of the E’ modulus as a function of temperature. By interpolating the tangent lines to the first two linear sections, we derive the Glass Transition Temperature (Onset).

- In blue: This curve identifies the temperature at which we have the maximum phase shift between the sinusoidal curves (the in-phase/elastic one and the out-of-phase/viscous one). Above this temperature, the analysed sample exhibits purely viscous behaviour. This point is known as the Peak Temperature.

The carbon fibre composite wires and segments we test have a glass transition temperature (Onset) that varies within the 190÷220 °C range.

Image Gallery

Related products

-

ACCM (Aluminium Conductor Composite Multistrand)

Made up of several composite elements in thermo-resistant carbon fiber stranded together it is more flexible and safer than any other conductor

Read More → -

ACCS (Aluminium Conductor Composite Single)

ACCS brings together all the best features of ACCM and manages to be even more competitive.

Read More → -

ACCS-Sens (Aluminium Conductor Composite Single)

ACCS-Sens involves the insertion of optical fibres in direct contact with the carbon core, allowing the integrity of the core to be monitored.

Read More →