Home » Products » Surface treatments » Sandblasted

Surface treatments

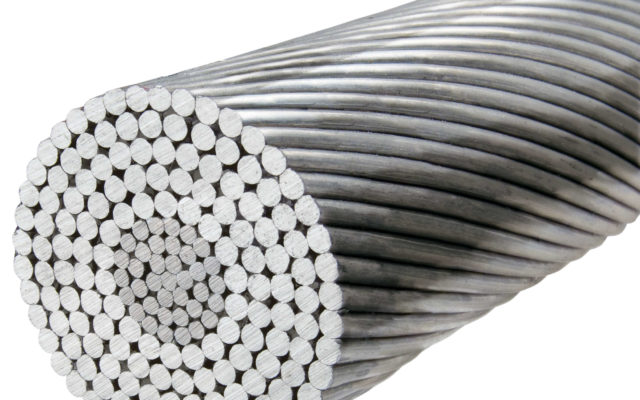

Sandblasted

De Angeli Prodotti has developed a process for sandblasting the outer layer of conductors to reduce the corona effect.

Introduction

The drawing of the aluminum wires of the outer layers of the conductors for overhead lines takes place in an oil bath. This process involves an external surface of the complete conductor slightly hydrophobic, which in particular environmental conditions, such as rain and high percentage of humidity in the air, causes the corona effect (corona noise) which produces an annoying hum of the overhead lines, limiting their acceptability by locals.

De Angeli Prodotti proposes a surface treatment of the outer layer of the conductor that allows to reduce the corona effect.

Engineering

De Angeli Prodotti developed a very effective sandblasting process to make the surface of the conductor hydrophilic and to reduce the corona effect by many dB.

The sandblasting process can be applied to all conductors in any formation and diameter.

The high noise reduction (corona noise), under different environmental conditions, has been confirmed by numerous tests performed in external accredited laboratories.

Advantages

The sandblasting of the conductors has 3 advantages:

- significant noise reduction (corona noise);

- reduction of the shining effect of the conductors;

- increase in emissivity (0,5);

resulting in increased social acceptability of overhead power lines.

Download

Paper Sandblasted Conductors vertical_align_bottomDownload PDF