The 120-tonne Tensile Testing Machine is an advanced testing platform designed for the mechanical characterisation of conductors intended for high-voltage overhead lines. The availability of a test bench of this size represents a key strength of our laboratory.

Thanks to its horizontal layout, the machine allows for testing long samples, up to 20 metres, making it ideal for simulating realistic operating conditions. This instrument is essential for studying the behaviour of materials under both static and dynamic conditions.

Operating principle and instrumentation

Il funzionamento si basa sull’applicazione controllata di una forza di trazione su un campione, fissato tra The operation is based on the controlled application of a tensile force to a sample, which is secured between two grips.

- The load is applied stably and progressively by an electric motor system with worm screws, guaranteeing reliability and repeatability of the tests.

- The exerted force is measured with precision by a 120-tonne load cell.

- The conductor’s elongation is detected by a pair of laser optical extensometers, a non-contact technology that eliminates errors due to twisting or lateral movements.

The entire process is managed by dedicated software that synchronises the collection of force and displacement data.

For high-temperature tests, the machine has a high-current heating system (up to 3000 A), with accurate temperature control via software and thermocouples.

Analysis and testing capabilities

The machine is not limited to break tests but allows for a wide range of tests:

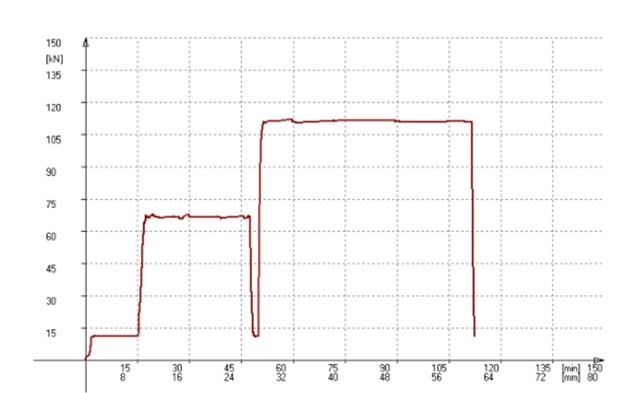

- Load/unload cycles (Fig. 1) to simulate real operating conditions and evaluate the fatigue resistance of materials.

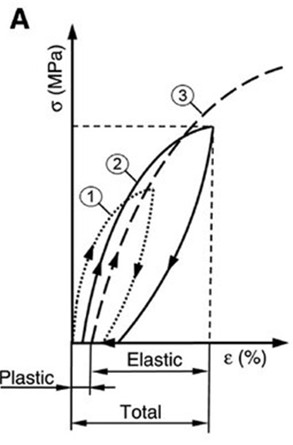

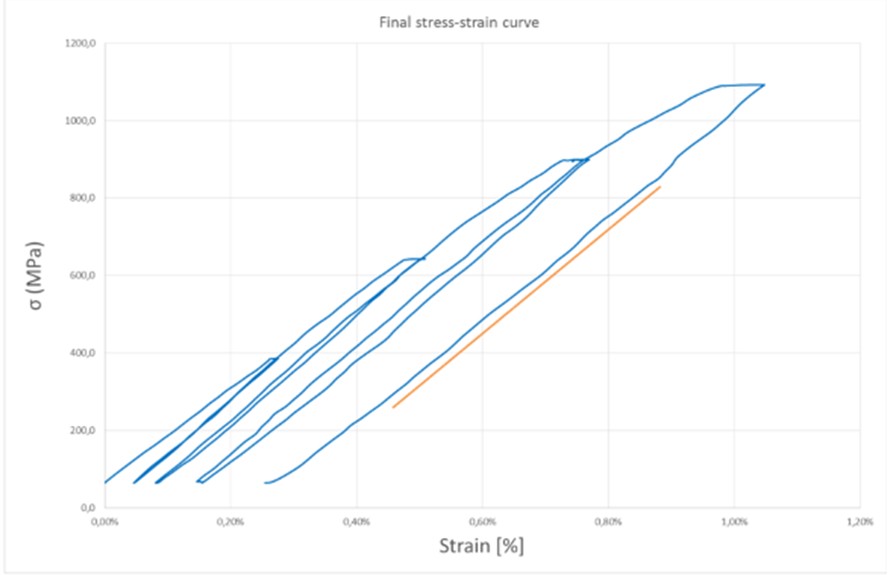

- Generation of the stress-strain curve (σ-ε), which describes the relationship between applied tension and elongation (Fig. 2). The analysis allows for the determination of key mechanical parameters, such as the material’s breaking load.

- Study of the creep phenomenon, i.e., the progressive elongation that occurs when a conductor is subjected to a constant load under high-temperature conditions. This provides fundamental data on the long-term stability of conductors in service.

Image Gallery

Related products

-

ACSR conductor (Aluminum Conductor Steel Reinforced) / ACSR-AW

ACSR conductor is the type of conductor most used worldwide and it is composed of a steel core and one or more hard drawn aluminum layers.

Read More → -

ACCM (Aluminium Conductor Composite Multistrand)

Made up of several composite elements in thermo-resistant carbon fiber stranded together it is more flexible and safer than any other conductor

Read More →