Litz wire or Litz cable is a very useful tool for power electronics because it allows you to create low-resistance, high-current conductors at frequencies up to hundreds of kHz!

The Litz wire or Litz cable is a very useful tool for power electronics because it allows the creation of low resistance and high current conductors at frequencies up to hundreds of kHz! However, using it effectively is not easy: one must take into account numerous physical and design aspects to optimize the product specifically for each use, minimizing losses.

Summary

- 1 Basics of electromagnetism

- 2 Litz wires: characteristics

- 3 Types of Litz wires

- 4 How to choose Litz wires

- 5 De Angeli Prodotti Litz wires

1. Basics of electromagnetism

To choose a Litz wire suitable for the operating parameters, it is useful to have at least a basic knowledge of the fundamentals of electromagnetism, especially regarding the skin effect and proximity effect that occur in a conductor carrying alternating current.

Simplifying, the skin effect indicates the tendency of alternating electric current to distribute on the external surface of the conductor, making the innermost part of it unusable. This tendency is amplified as the working frequency increases.

The proximity effect, on the other hand, indicates the tendency of alternating current to create electromagnetic fields capable of influencing nearby conductors to the point of causing interference and signal losses.

2. Litz wires: characteristics

Litz cables (or Litz wires) are made up of many thin enameled wires, which are twisted and intertwined with each other. They are designed to operate at high frequencies, reducing the size of the transformer.

2.1 What are Litz wires?

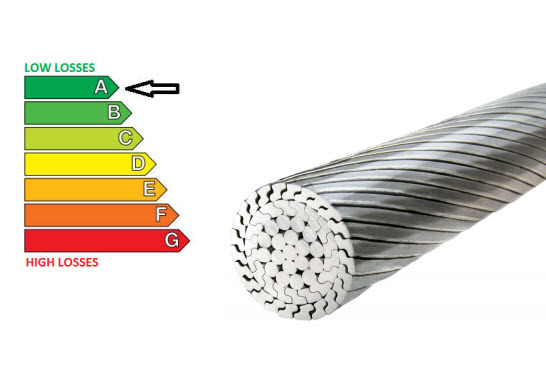

Litz cables are conductors made up of numerous thin wires twisted together to limit the current losses due to various factors including the skin effect, which occurs especially at high frequencies. In practice, alternating current tends to distribute more on the external surface of the conductors, making a part of them unusable and causing energy losses. The use of Litz cables allows limiting these losses and increasing the efficiency of energy transfer. Additionally, Litz cables have a random bundle and extruded thermoplastic coatings to minimize the proximity effect on nearby conductors.

2.2 What are Litz wires used for?

In addition to reducing electrical losses at high frequencies, Litz cables allow for significant size reduction. In fact, in an electrical winding, the number of turns and the magnetic flux are inversely proportional to the current frequency. For this reason, Litz wires are perfect for applications requiring the use of small-sized, high-performance, flexible, and low-loss transformers.

2.3 Why choose Litz wires?

- Flexibility: being made up of numerous individual enameled wires, the Litz cable is more flexible than a single conductor of the same section. Performance: thanks to their “twisted” construction and the presence of multiple electrically insulated wires, Litz cables can handle high frequencies without significant signal losses.

- Efficiency: thanks to the reduction of electrical losses, Litz cables have higher efficiency in many applications, such as transformers. Moreover, their electrically isolated construction helps to reduce parasitic current loss as well.

- Versatility: Litz wires can be used wherever high frequency performance is required, such as in transformers, inductors, antennas, speakers, measuring instruments, medical equipment, and more.

3. Types of Litz wires

Litz wires are available in many design options depending on the number of wires and the configuration of the bundle.

3.1 Design

The production of high-frequency Litz wires involves the use of multiple electrically insulated single wires, typically used in applications operating in a frequency range from 10kHz to 5 MHz. In high-frequency coils, parasitic current losses increase, caused by the skin effect and proximity effect. The use of Litz wires reduces these effects thanks to their twisted construction, which compensates for the magnetic field that generates the losses.

The concept behind Litz wire is therefore very simple: to create a braided wire in which the fundamental units are enameled wires with a diameter smaller than the skin depth. In this way, the Litz wire will not be affected by the related effect, and high-frequency losses will be significantly reduced.

3.2 Introduction to Litz wire terminology

- Single wire: it is the basic component of Litz wire construction, consisting of a single conductor material wire (e.g. copper) with a thin layer of insulating varnish that prevents electrical contact with other wires or other parts of the circuit. The single wire is used to build the bundle of Litz wires.

- Litz wire bundle: it is a combination of electrically insulated single wires to reduce parasitic current losses and improve high-frequency performance.

- Twist pitch: it is the distance that a wire needs to complete a full rotation around the circumference of the Litz wire.

- Twist direction: it is the direction of the twist (or grouping direction) of the wire structure in bundles. It can be right (Z) or left (S).

3.3 Types of Litz wires

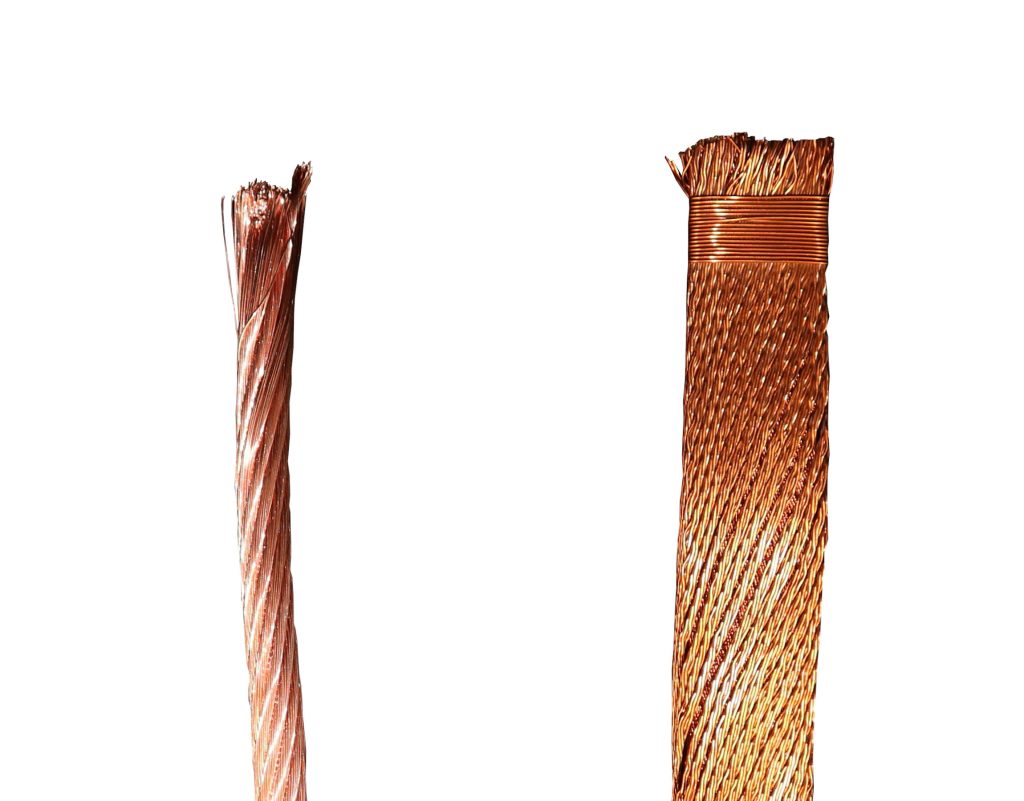

- Random bundle Litz wires: It is a configuration in which a certain number of single wires are grouped together in such a way that each single wire can occupy any position within the cross-sectional area of the bundle, without following a predetermined twisting pattern of the wires. This type of configuration helps to reduce parasitic current losses and increases the flexibility of the wire, as the individual wires can move freely within the bundle.

- Concentric Litz cables: it is a configuration of single wires arranged in one or more concentric layers around the central conductor of the Litz wire. During the twisting operation, each single wire naturally moves into its predetermined position, obtaining consistent working dimensions and properties. In this way, the concentric wire twisting construction allows obtaining a uniform distribution of the electrical and mechanical properties of the Litz wire.

- Multi-stage Litz wire: is a configuration where single wires are twisted in several stages to form different groups of twisted wires, which are then paired with each other in further twisting stages to achieve greater flexibility while maintaining high performance at high frequencies.

4. How to choose Litz wires

To choose the most suitable Litz cable, some factors must be taken into consideration, such as the operating frequency, required power, cable length, presence of electromagnetic interference, and the usage environment. Moreover, the section of the single conductive wires, type of insulation, and number of interwoven wires must be carefully evaluated to ensure optimal cable performance.

It should be noted that there is no unique formula for choosing the best Litz cable for a specific application. Therefore, it is necessary to have knowledge of both the electromagnetic properties of materials and the principles of electromagnetism to make the best choice. To this end, De Angeli Prodotti provides its customers with a team of highly qualified engineers to assist in system design and choose the best type of cable for every need.

5. De Angeli Prodotti Litz wires

De Angeli Prodotti invests in innovative technologies to produce high-quality and highly efficient Litz wires and cables. This commitment is also evidenced by the opening of the brand-new department in 2019 that produces some of the most innovative Litz cables on the market, which has been met with high demand from our customers. In this regard, the company has decided to invest in the purchase of three new highly-performing machines for Litz cable production, which will allow us to reach a production capacity of 40 tons per month by mid-year. With these new machines, we will be able to meet an ever-increasing demand and offer increasingly customized solutions for the diverse needs of the Litz cable market, using cutting-edge technologies in the sector.