Reduced line losses, easy installation and replacement, less CO2 production: all this is AAAC-SHC thanks to the high conductivity of Aluminum.

“Conductivity at its best”

Introduction

Aluminum alloy is already used by long time as material for overhead lines but the current technologies allow an improvement of conductivity.

The improvement of electrical conductivity of aluminum alloys is one of the main possible developments to obtain efficient, light and corrosion resistant conductors for low line losses.

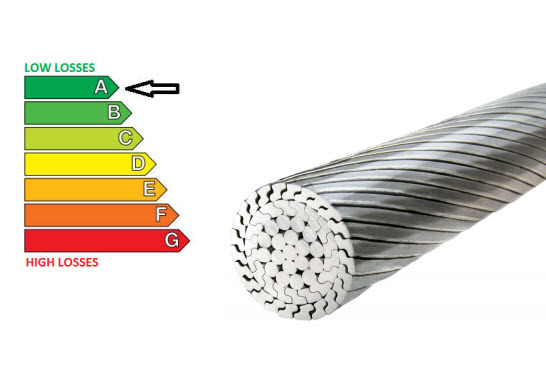

Nowadays, AAAC SHC are on the edge of technology for overhead lines in terms of energy efficiency.

Engineering

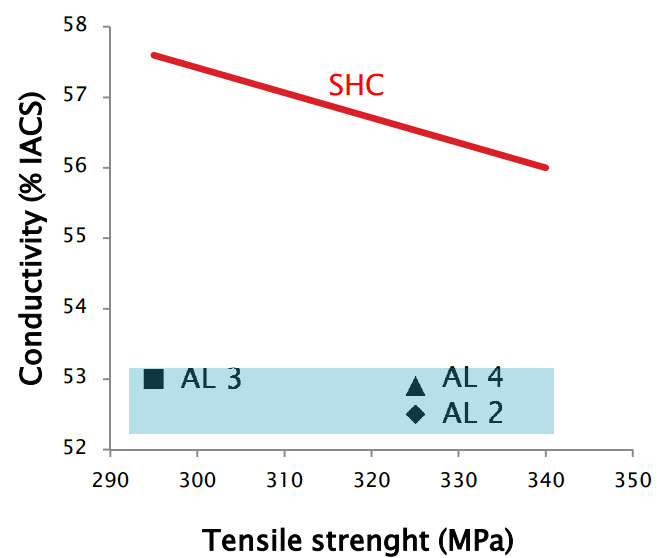

An accurate study of aluminum alloys properties and micro-structures has permitted to develop a material with a higher electrical conductivity compared to the traditional aluminum alloy used for conductors (AAAC), maintaining the same tensile strength in a better electrical conductor.

The conductivity of Aluminum Alloy Conductor with Super High Conductivity is described in the image below.

Minimum Tensile Strenght of Wire (MPa) | Maximum Resistivity of Wire (Ohm.mm²/m) | |

| ASTER 570AL 4 | 325 | 0.0329 |

| ASTER 570SHC | 325 | 0.0305 |

| Delta | = | -7.3% |

The enhanced electrical conductivity allows an energy losses reduction more than 7%.

Furthermore, De Angeli Prodotti and TCH De Angeli innovative production process gives the possibility to obtain extremely high conductivity for different requirements of tensile strength, in order to satisfy all the costumer’s requirement.

Advantages

- The line losses are reduced: more conductive aluminum alloy reduces line losses up to 7% compared to conventional AAAC conductors of the same size and weight;

- Easy installation or substitution: AAAC SHC conductors have the same section as the traditional one, so the substitution of the old lines can be performed without any problem. The new conductor can be installed exactly in the same way;

- Less power generation and reduced CO2 emission: lower line losses means less power generation and less CO2 emissions to serve the same load.

High-conductivity aluminum conductors offer several significant advantages in the electrical power sector. One of the main benefits is the reduction of line losses. Thanks to the increased conductivity of the alloy, line losses can be reduced by up to 7% compared to conventional AAAC conductors of the same size and weight. This not only leads to an overall improvement in system efficiency but also contributes to greater sustainability by reducing CO2 emissions associated with power generation. Additionally, the ease of installation or substitution is another point in favor of these conductors. Since they have the same section as traditional AAAC, replacing old lines can be done seamlessly, allowing for precise and hassle-free installation. This aspect is particularly advantageous in terms of cost reduction and downtime during maintenance or infrastructure upgrades.

In summary, the adoption of high-conductivity aluminum conductors not only improves the efficiency of the electrical system but also contributes to reduced environmental impact, making the energy sector more sustainable and efficient.

Conclusions

New aluminum alloy conductors developed by De Angeli Prodotti and TCH De Angeli give very important advantages compared to the traditional one, the installation of this new product assures an important decrease in energy losses.