Untreated conductors have a lower emissivity. But what is emissivity and how can we increase it?

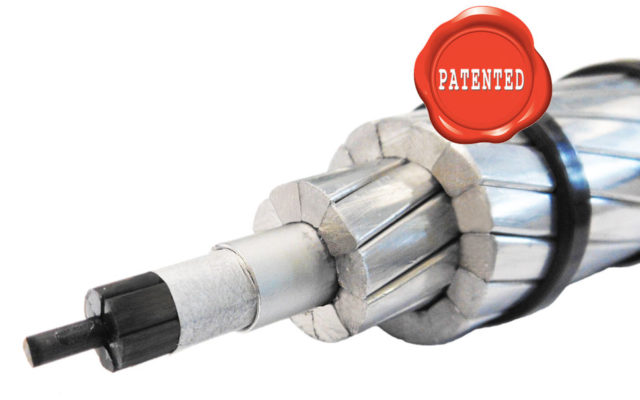

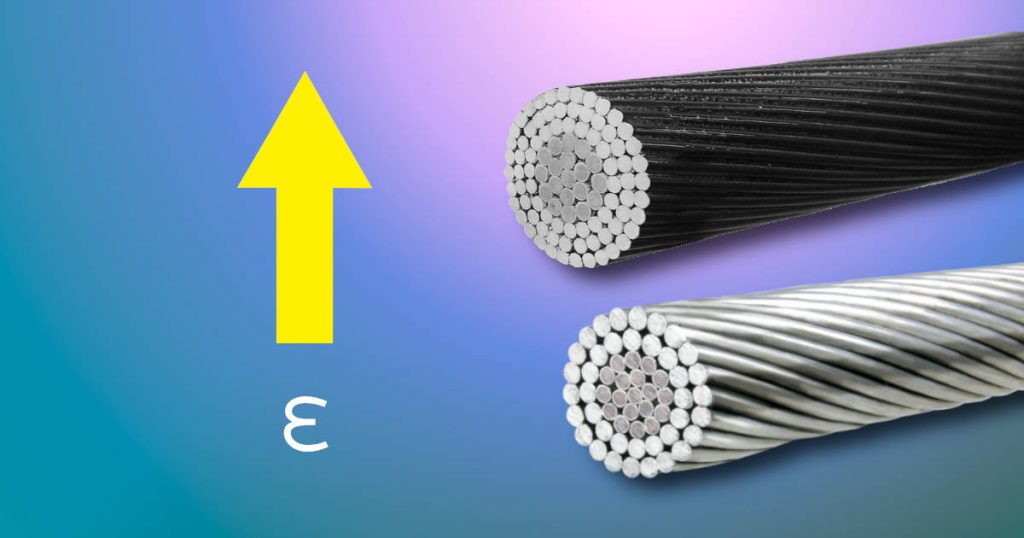

Conductors of overhead power lines have a reflective surface especially if they have been recently installed or even after many years in low-pollution mountain environments. This is due to the fact that the outer layer of most high voltage conductors, made up by drawn aluminum wires, is not subject to surface treatments which cause its properties to change. Commonly an untreated (shiny) conductor is characterized by an emissivity of around 0,5.

What is emissivity and how is it measured?

The emissivity of a surface is defined as the ratio between the radiation emitted by the surface and the radiation emitted by the black body at the same temperature.

Emissivity is indicated with ε, it varies between zero and one (0≤ ε ≤1) and is a measure of how much a real surface approximates a black body for which ε = 1. The emissivity of a real surface is not constant but varies with the surface temperature, with the wavelength and with the direction of the emitted radiation.

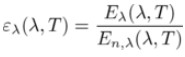

In practice, the direction effect is neglected by averaging over all directions and consequently denoting the emissivity as hemispheric. The dependence on the wavelength can instead be significant and therefore the monochromatic hemispherical emissivity is used and is indicated with ελ that is defined with this expression:

Total hemispheric emissivity ε is instead averaged over all directions and wavelengths and is expressed with the relationship:

This latter formula is commonly used in practice to characterize the emissive properties of surfaces although these depend on both the direction and the wavelength. We therefore speak of grey and scattering bodies, meaning that their properties are independent of wavelength and direction respectively.

Why increase the emissivity of a conductor for overhead power lines?

A higher emissivity value corresponds to a greater quantity of radiation emitted at the same temperature. This means that a conductor with higher emissivity, with the same current range, environmental conditions and structure of the conductor, operates at lower temperatures as it can better disperse its heat in the environment.

Generally speaking, an HTLS (High Temperature Low Sag) conductor with a coloured surface will be characterized by a greater ampacity at the same operating temperature compared to the same untreated conductor.

Which are the benefits of a coloured conductor?

The colouring of the external surface of the conductors has two main advantages:

- An increase in surface emissivity (up to 0.8) which, in the case of HTLS (High Temperature Low Sag) conductors, increases the ampacity at the same operating temperature.

- A substantial reduction in the visual impact of the overhead power line, especially in wooded environments, parks and protected areas, which leads to better harmony with the external environment and greater acceptability.

The most used colours are green and black, but the process is applicable to any colour, to conductors of any formation and diameter and the installation does not need particular difficulties and precautions.

In the image below you can see how a colored conductor is almost invisible against a green and wooded background.