This is an instrument that no company laboratory should be without.

One of the main properties of the materials processed in our company is their mechanical characteristics.

Metals, by their nature, are elasto-plastic materials: they possess both elastic and plastic characteristics.

The sample to be tested is simply a straight piece of the product (rectangular wire, round wire, or trolley wire) with a length of about 30-35cm.

This is secured at its ends by two grips, and an extensometer is also positioned on it.

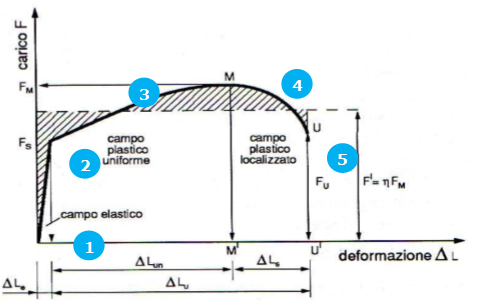

During this mechanical test, the sample is subjected to an increasing mono-axial force, which triggers a deformation process that develops in several phases.

The graph highlights the phases of the mechanical tes

- Phase 1 is characterised by a linear elastic deformation behaviour that follows the physical rules of Hooke’s Law: if the applied force returned to zero, the sample would return to its initial state.

- This behaviour occurs up to approximately 0.2% elongation, when the yielding of the sample occurs (Phase 2), “Micro-cracks” form on the sample

- Subsequently, plastic behaviour occurs (Phase 3), which is irreversible deformation.

- The plastic deformation continues until the phenomenon of necking (Phase 4 or localised plastic), which manifests as a reduction in the cross-sectional area of the sample.

- The test ends with the fracture of the sample (Phase 5).

The tensile machine in the laboratory (Galdabini or Lloyd) displays the sample’s behaviour on a graph, but the software is also able to provide us with the main test values: Rp0,2% (Proof Strength) and Ultimate Load and Elongation at break.

Image Gallery

Related products

-

Enamelled conductors

De Angeli Prodotti enamelled wires are available in copper and aluminum. The configuration possibilities are many: choose the ideal solution for your projects.

Read More → -

ACSR conductor (Aluminum Conductor Steel Reinforced) / ACSR-AW

ACSR conductor is the type of conductor most used worldwide and it is composed of a steel core and one or more hard drawn aluminum layers.

Read More → -

ACS (Aluminium Clad Steel)

The ACS (Aluminium Clad Steel) rods are installed as an alternative to the traditional galvanized steel ground wires for the protection of overhead power lines from lightning.

Read More → -

Contact wire (Trolley)

The contact wire “trolley” is the most important conductor of the railway infrastructure.

Read More →