Tangentdelta

This is a must-have tool for any corporate laboratory. With this tool, we can visualize the dissipation factor (D-Value) as a function of temperature. The deposited enamel is polymeric in origin, and the thermal properties observed vary depending on the type of molecular structure.

The production of insulated products can be achieved by depositing enamel onto the surface of a conductor (copper or aluminium).

The deposited enamel is polymer-based, and different molecular structures result in different thermal properties.

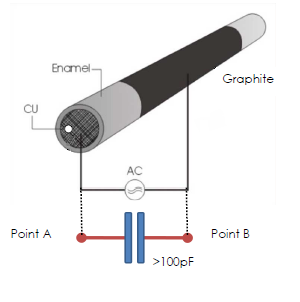

With this instrument, we display the dissipation factor (D-Value) as a function of temperature. To perform this measurement, it is necessary to transform the enamelled wire (or enamelled rectangular wire) sample into a capacitor (Figure 1). This is done by depositing a graphite solution (a conductive material that is chemically inert towards the enamel).

An alternating current is applied to this small capacitor, and the sample is heated.

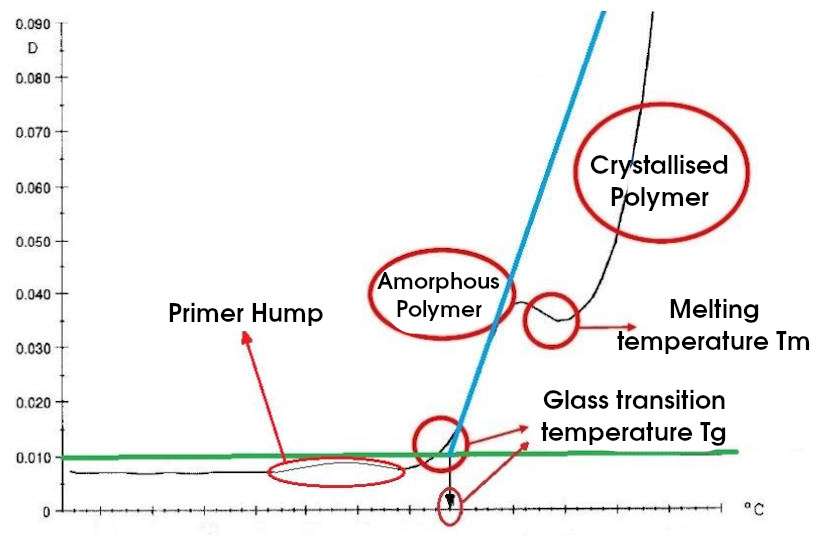

Temperature serves to provide energy to the polymer’s molecular chains, leading to a change in its structure from completely amorphous (i.e., a disordered intermolecular structure), characterised by low dissipation factor (D-Value) values, to a completely crystallised polymer (a very ordered intermolecular structure), which also allows current to pass, resulting in high dissipation factor values.

The dip between the amorphous section and the section identifying the crystallised polymer can have various causes; among the main ones are: the thermal treatment of the enamel (curing) and the electrical mobility of the molecular chains.

Through graphical interpolation, it is possible to derive the Tangent Delta temperature, which identifies the correct polymerisation (curing) of the enamel. In our sector, this output temperature is somewhat improperly linked to the thermal class of the enamelled wire (or rectangular wire), as the thermal class is actually determined by a long-term durability test.

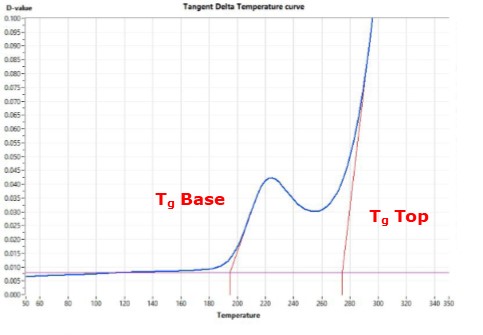

In the example to the side (Figure 3), we see the graph for a Thervest 200 copper wire with a Tangent Delta of 195°C.

Figura 3: Practical example of a test on Thervest 200 with a Tangent Delta value of 195°C