De Angeli Prodotti has developed an innovative wire to improve the electrical performances of magnet wire.

Getting more with less – “Corona Resistant Magnet Wire”

Introduction

The standard enamelled wire used for winding is produced using a quite old process. Today is possible to build a new type of conductor using the best technology available on the market, to optimize the electrical performance allowing the reduction of the overall thickness of enamel.

Looking to the future, De Angeli Prodotti accepts the challenge to innovate the enamelled wire.

One solution that can help to resolve different problems.

Engineering

De Angeli Prodotti is developing a new technology looking towards a new solution:

a thin layer of paint is deposed on the conductor, by enameling the varnish on it. After this phase, a curing is necessary to allow the paint to adhere to the surface and obtain the desired performances.

Advantages

Which are the advantages of this technology?

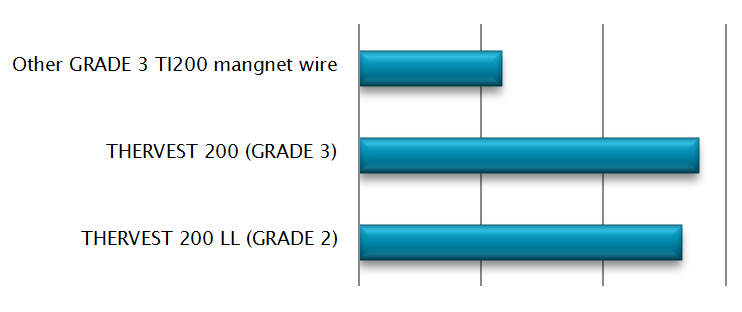

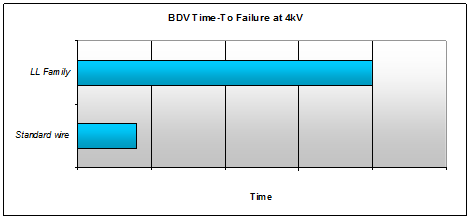

Our laboratory tests shown that Corona Resistant Family significantly improves dielectric performance under continuous electrical solicitation. In this field Corona Resistant Grade 2 performance is comparable to a standard Grade 3 wire at 4 and 8kV.

Other test performed at 4 kV confirm this behaviour and show that “Corona Resistant” Family can resist five times the standard wire.

This means less coatings, longer life and higher filling factors.

Conclusions

De Angeli Prodotti has developed an innovative wire to improve the electrical performances of magnet wire.

This technology is well known for us and the costumer interest for this product is very high.