Guard ropes are often installed on overhead lines to protect them from any disruptions. But can they have other purposes?

Overhead power lines can be subject to lightning phenomena that causes serious damage to the line this make necessary the phase or phases replacement. The installation of a new conductor requires the inactivity of the entire section involved causing out-of-services.

To avoid this type of problems, ground wires are very often installed at the upper end of the towers. These have the unique purpose of protecting the underlying phases from lightning by acting as a “expendable component”, in fact, it is not electrified. For this reason, the replacement of the guard rope does not require the shutdown of the line and thus the inefficiency is avoided.

How to make the ground wire really useful?

It is possible to carry out data transmission through optical fibers positioned inside the ground wires which are called OPGW (Optical ground wire). For about 20 years, all TSO (Transmission System Operators) have been gradually replacing all guard ropes with OPGW also driven by the ever higher demand for faster and more capillary data transmissions.

What is an optical fiber?

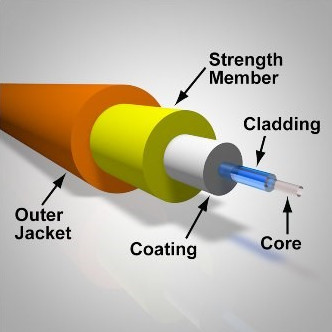

Optical fibers are filaments of glassy or polymeric materials, made in such a way as to be able to conduct light inside them. Optical fibers are classified as dielectric waveguides: the optical fiber can simply be thought as a pipe through which light flows, comparable to a tube through which water flows.

In other words, they allow an electromagnetic field of sufficiently high frequency (generally in the vicinity of the infrared) to be conveyed and guided inside them with extremely limited losses. A rigorous study of the physics of optical fibers requires concepts of quantum optics.

Using a comparison with classical optics, in optical fibers a phenomenon of total internal reflection occurs, whereby the discontinuity of the refractive index between the materials of the core (higher refractive index) and of the cladding (lower refractive index) traps the radiation luminous as long as this maintains a fairly grazing angle, in practice until the fiber makes too sharp bends.

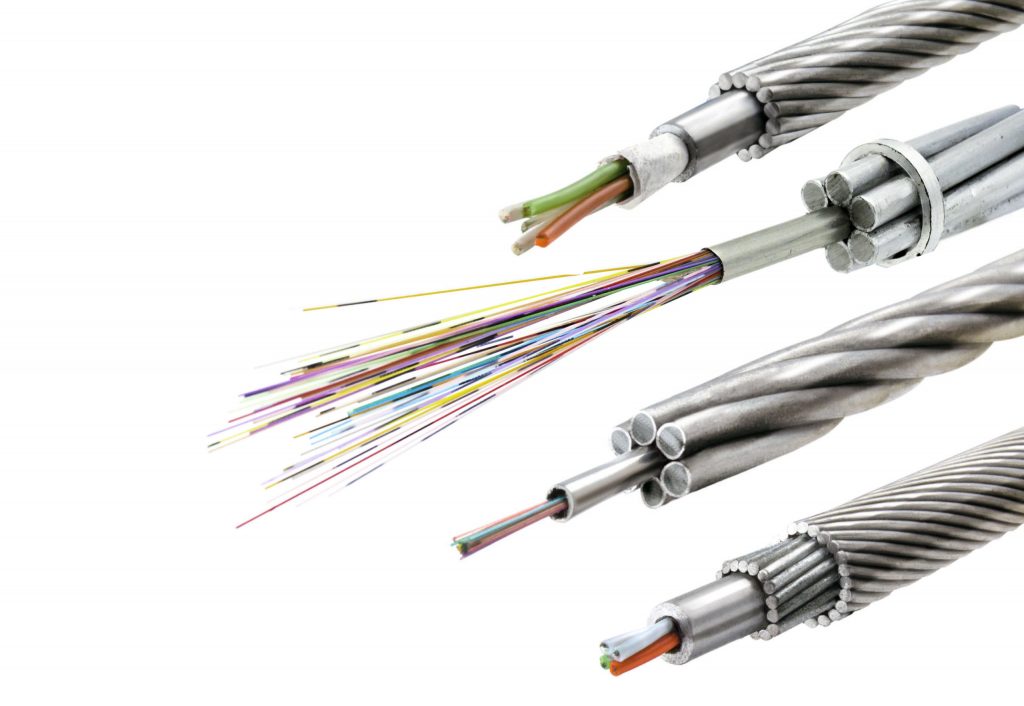

How is an OPGW made?

The design of an optical guard wire is not standardized but there are several possible configurations. Its structural part, in most cases, is made of galvanized steel or ACS (Aluminum clad steel). The optical fibers are positioned inside one or more stainless steel or Al aluminum tubes. Sometimes the use of Inox-Al bimetallic tubes is required.

Depending on the size, the loose tubes contain dozens of optical fibers, typically in multiples of 24 units (24, 48, 96, etc.). The optical cores are filled with a gel to prevent moisture and water from penetrating inside. Depending on the needs, these loose tubes can be positioned in the central position or in the crown. In general, it is avoided to position them on the outer shell so that they can be protected during the installation phases and during the life of the ground line itself. De Angeli Prodotti is able to produce OPGW in all its conformations.

What are the advantages of OPGW?

The major advantage of this particular guard rope lies in the combination of two features:

- Protection of overhead power lines from lightning;

- Creation of a capillary infrastructural network for data transmission.