Fiber in Metal Tubes (FIMT) protect optical fibers in extreme environments, ensuring reliability and intelligent monitoring for increasingly smart energy networks.

Fiber in Metal Tubes (FIMT) represent one of the most advanced technological solutions in telecommunications and energy infrastructure. They are small metal tubes that protect the optical fibers inside from mechanical stress, external agents, and extreme environmental conditions, ensuring reliability and continuous service even in the most challenging contexts. Thanks to their versatility, FIMTs are used in optical ground wire (OPGW) and active line cables (OPPC), in underground and submarine networks, as well as in innovative projects related to smart grids. They can be customized in terms of diameter, number of fibers, and materials, making them compatible with all major international standards. Their dual function – data transmission and real-time distributed monitoring – makes them essential for predictive maintenance and operational efficiency. In this article, we aim to answer your questions about FIMTs and show why our company is your strategic partner for building safer, smarter, and more sustainable networks.

Summary:

- 1. What are FIMT?

- 2. What are the applications of FIMT?

- 3. Can FIMT be customized or adapted to a project?

- 4. What materials are used to produce FIMT?

- 5. Technical characteristics of FIMT

- 6. What advantages do FIMT offer?

- 7. What is the added value of De Angeli Prodotti and why choose it as a partner?

- 8. What does the future hold for the use of FIMT?

1. What are FIMT?

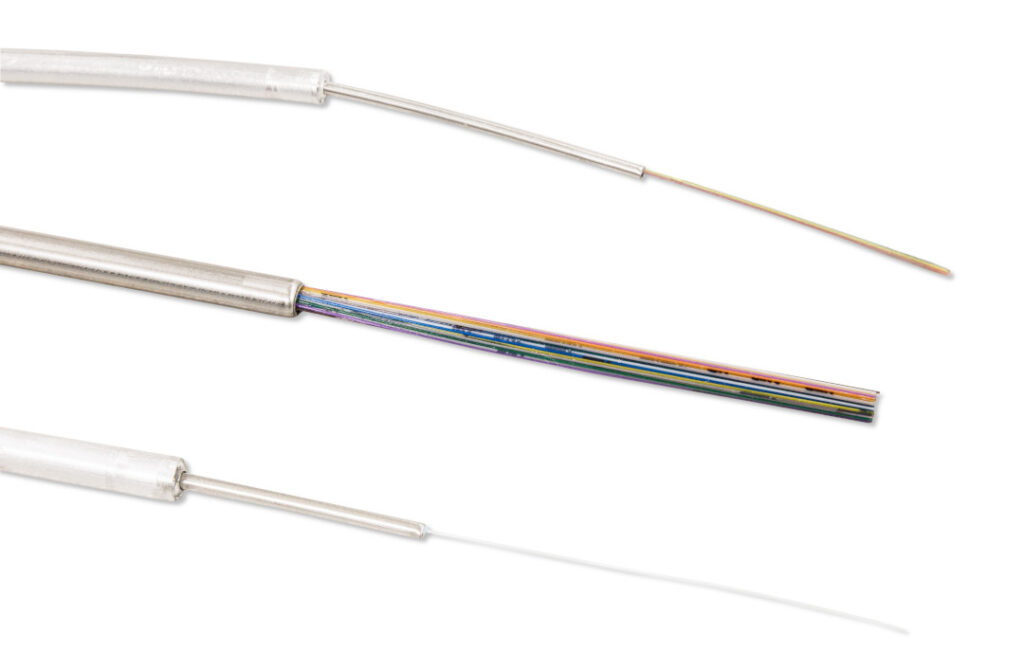

Fiber in Metal Tubes (FIMT) are highly specialized components designed to integrate optical fibers within a continuous metallic coating, ensuring protection and reliability even in environments where mechanical stress, chemical agents, humidity, and temperature variations could compromise their functionality. They are small metal tubes, typically made of stainless steel or high-performance superalloys, inside which one or more optical fibers are inserted. Thanks to these features, FIMTs represent an ideal solution for high- and medium-voltage applications (such as OPGW – Optical Ground Wire, OPPC – Optical Phase Conductor, underground, and submarine cables). In addition to supporting data transmission in critical contexts, FIMTs play an increasingly central role as advanced sensors for distributed monitoring: they can measure parameters such as temperature, strain, and vibrations in real time, enabling predictive and proactive maintenance functions. The high compatibility with international optical fiber standards (G.652D, G.655, G.657A1, etc.) and the ability to customize in terms of diameter, number of fibers, and materials make FIMTs a versatile technology, essential for next-generation energy and telecommunications infrastructures.

2. What are the applications of FIMT?

Fiber in Metal Tubes (FIMT) are used in multiple critical environments where robustness, protection, and reliability are essential. For example, in the Oil & Gas sector, FIMTs are crucial for implementing advanced sensing systems for well completions, coiled tubing operations, and slickline interventions. This is because they ensure accurate real-time monitoring and reliable data collection even under demanding operational conditions. Regarding the marine sector and the use of submarine cables, the hermetic structure of FIMTs is ideal for protecting optical fibers from hydrostatic pressure, corrosion, and harsh aquatic environments. Industrial applications include data center cables, industrial monitoring, cryogenic environments, and logging and downhole systems. Furthermore, they are used in civil infrastructures such as buildings, bridges, tunnels, pipelines, and underwater environments, where stable data transmission and structural monitoring through metal-protected integrated optical fibers are required.

3. Can FIMT be customized or adapted to a project?

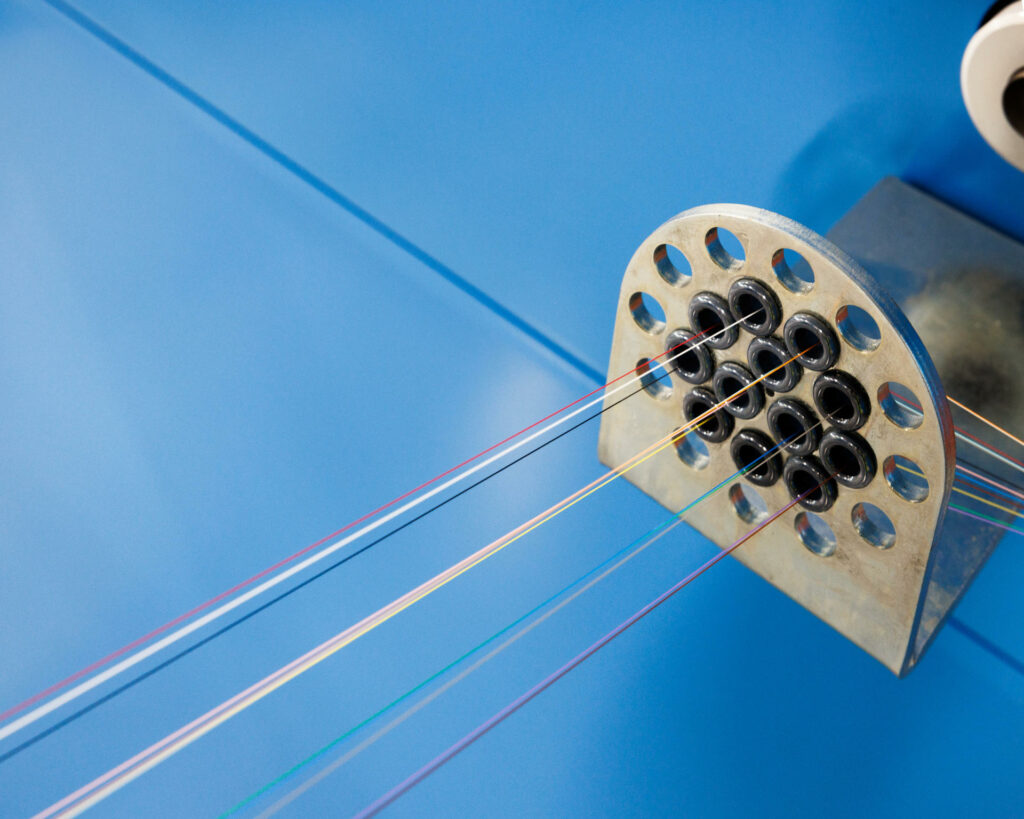

One of the main reasons we chose to invest in this technology by acquiring the machinery necessary to develop highly specialized products is its extreme versatility, which allows it to be designed and customized according to the specific requirements of each project. Indeed, every application presents unique requirements, such as the tube diameter, the number of integrated optical fibers, the type of fiber used, and the materials of the metallic coating. De Angeli Prodotti offers a complete range of configurations, from small, extremely compact tubes to larger diameter solutions capable of hosting a high number of fibers without compromising their protection.

This design flexibility allows FIMTs to be integrated into all advanced telecommunications and energy infrastructure networks. Furthermore, the ability to use different types of fibers (single-mode or multi-mode, according to international standards) provides additional adaptability depending on the required performance. Thanks to this tailored approach, De Angeli Prodotti ensures efficient and reliable solutions that maximize system lifespan and support the development of next-generation smart grids.

4. What materials are used to produce FIMT?

The choice of materials is a crucial aspect in the production of Fiber in Metal Tubes (FIMT), as it determines the mechanical strength, durability, and reliability of the integrated optical fibers. FIMTs are generally made of stainless steel, a material that provides excellent corrosion protection, high resistance to impact and mechanical stress, and outstanding performance even in environments characterized by significant temperature fluctuations. In applications requiring an additional level of protection or lightness, it is possible to use stainless steel with an aluminum coating, a combination that merges the strength of steel with the shielding and lightweight properties typical of aluminum. This solution is particularly effective when FIMTs are integrated into cables designed for harsh operating conditions, such as high and medium-voltage overhead networks, submarine cables, or complex industrial environments. The use of high-quality metallic materials ensures the perfect hermetic sealing of the tube and the protection of optical fibers from external agents such as humidity, chemical substances, or high pressure. Through continuous research and selection of the best available alloys, De Angeli Prodotti is able to offer tailor-made solutions that meet specific design requirements, ensuring long-term reliability and high performance.

5. Technical characteristics of FIMT

Fiber in Metal Tubes (FIMT) stand out for a range of technical features that make them a reliable and versatile solution for critical applications in the energy and telecommunications sectors. The available configurations cover a wide range of outer diameters, from 1.15 mm up to over 5 mm, with the capability to host up to 48 optical fibers within a single tube. The metal wall thickness, precisely calibrated according to the final application, ensures the right balance between compactness, mechanical strength, and flexibility.

6. What advantages do FIMT offer?

Fiber in Metal Tubes (FIMT) offer numerous advantages that make them the ideal choice for high-reliability applications in the fields of telecommunications and energy infrastructure. The first benefit is their superior mechanical protection: the metallic sheath ensures that the optical fibers are shielded from impacts, tension, and vibrations, maintaining signal continuity even under extreme environmental conditions. Added to this is their resistance to corrosion and external agents. Another key advantage, as highlighted in the previous section on customization, is their design versatility: FIMTs can be manufactured in different configurations, sizes, and materials, adapting to the specific requirements of each project. This flexibility allows the tubes to be integrated both into standardized cables and into custom solutions for smart grids and intelligent networks. Thanks to their compact structure, FIMTs also enable a high fiber density without compromising the overall cable strength, optimizing both space and performance. Finally, their ability to operate as distributed sensors for real-time monitoring of temperature, strain, and vibrations represents a strategic added value, supporting predictive maintenance and operational efficiency.

7. What is the added value of De Angeli Prodotti and why choose it as a partner?

Il vero vantaggio competitivo di De Angeli Prodotti risiede nella capacità di coniugare competenze ingegneristiche avanzate, innovazione continua e una forte attenzione alle esigenze specifiche di ciascun cliente. A differenza di altre aziende che forniscono componentistica standard, noi abbiamo scelto di concentrarci nel dare soluzioni su misura che rispondono in modo mirato alle condizioni operative di ogni progetto, dalle infrastrutture energetiche di nuova generazione alle reti di telecomunicazioni ad alte prestazioni. La combinazione di un rigoroso controllo qualità, di materiali selezionati e processi produttivi all’avanguardia garantisce affidabilità e durata nel tempo in qualsiasi condizione operativa. Inoltre, De Angeli Prodotti si distingue per un approccio consulenziale: non si limita a fornire un prodotto, ma accompagna il cliente in tutte le fasi, dall’analisi preliminare alla progettazione fino all’implementazione e al supporto post-vendita. Questo modello di collaborazione, basato su trasparenza, flessibilità e rapidità di risposta, consente di ridurre i tempi di sviluppo e di aumentare l’efficienza complessiva delle reti. Scegliere De Angeli Prodotti significa quindi affidarsi a un partner in grado di offrire un valore aggiunto tangibile alla transizione verso infrastrutture intelligenti, resilienti e sostenibili.

8. What does the future hold for the use of FIMT?

The future of Fiber in Metal Tubes (FIMT) is closely tied to the evolution of smart infrastructures and the growing need for real-time monitoring of energy and telecommunications networks. With the expansion of smart grids and the increasing integration of renewable energy sources, FIMTs will play a central role in ensuring the safety, resilience, and efficiency of these networks. Their ability to protect optical fibers while simultaneously functioning as distributed sensors, capable of detecting temperature, strain, and vibrations, makes them indispensable tools for enabling predictive maintenance and intelligent system management. Looking ahead, we will witness a growing adoption of FIMTs, especially in the increasingly complex environments brought by technological progress, from next-generation submarine cables to critical civil infrastructures. At the same time, the development of innovative materials and more compact configurations will make it possible to increase fiber density and expand application possibilities, while maintaining high reliability standards. Thanks to its strong commitment to research and development, De Angeli Prodotti will continue to be a key player in this transformation, offering tailor-made solutions that anticipate market needs and support the energy transition.