De Angeli Prodotti is developing a new kind of product named FORVEST F flat wire: the advantages are a higher thermal class compared to PVA/PVF standard coating, together with the best flexibility, good adhesion and high surface hardness.

“Get more from your trafo”

De Angeli Prodotti is developing a new kind of product named FORVEST F flat wire: the advantages are a higher thermal class compared to PVA/PVF standard coating, together with the best flexibility, good adhesion and high surface hardness.

Introduction

Standard flat wires used to make CTC’s are coated using PVA/PVF resins. This is a typical and mature product configuration, historically used in oil filled transformer.

The thermal class reached by PVA/PVF resins is around 120°C (thermal class E).

Modern market’s demand is addressing to a new type of conductors using new materials and technologies , optimizing the overall thermal performance.

Looking to the future, De Angeli Prodotti picks up the gauntlet to innovate flat wires for oil-immersed machines with a solution solving different issues.

Engineering

De Angeli Prodotti is developing a new technology looking towards a new solution: a thin layer of paint is deposed on the conductor, by enameling the varnish on it. After this phase, a special curing is necessary to allow the paint to adhere to the surface and obtain the desired performances.

Advantages

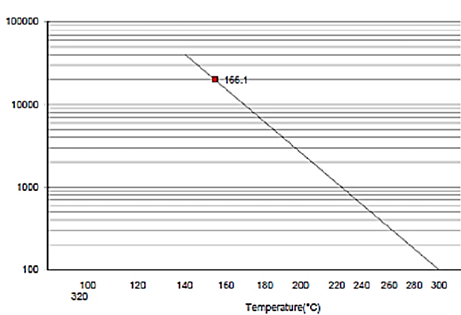

FORVEST F flat wires allow to reach higher thermal class as verified in cooperation with our suppliers: the minimum value guarantee 155°C (thermal class F).

Its outstanding flexibility, adhesion and surface hardness reached using our special enameling process, make every single strip suitable for being processed in a transposing machine, avoiding any kind of mechanical defect inside the finished CTC cable. This means more thermal endurance and more reliability for the final users.

Conclusioni

De Angeli Prodotti is developing an innovative flat wire to improve the thermal performances of CTC cables.

This technology is under fast development in our internal departments and the thermal limits of oil-immersed machines are going to change for good!