Stronger as steel, light like aluminium.

How an ACCM Conductor is born

Stronger as steel, light like aluminium. We see the carbon fiber applications almost everywhere: from the first aerospace rockets up to military, automotive, buildings, sports, design and art. The material of the 21st century is now coming also in the electric field as reinforce for overhead conductors. But how it is produced?

How is carbon fiber made?

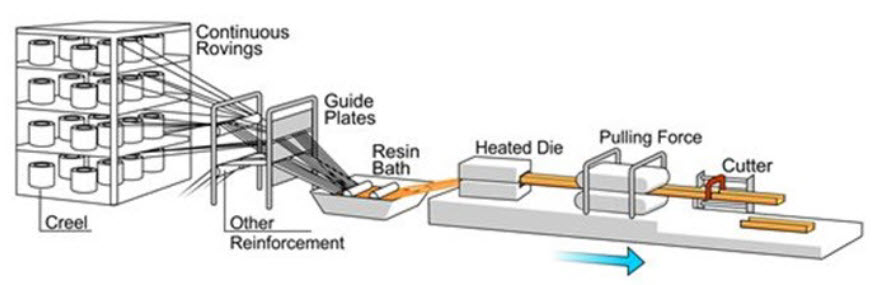

The production process of a carbon fiber wire is called pultrusion and it looks like an extrusion but it involves pulling of the work piece (so the prefix ‘‘pul-’’ is used in place of ‘‘ex-’’).

Like extrusion, pultrusion make continuous, straight profiles of constant cross section. Patented in 1959 by the Californian W. Brandt Goldsworthy, the pultrusion process, described in the below picture, requires a creel that contains several spools of carbon fiber rowing. The bath is the place where the fibers meet the liquid resin, after it takes place the hot die where the profile takes his shape becoming stiff, meanwhile a chemical reaction process occurs giving the thermal properties to the pultruded composite wire. Hydraulic pullers provide a continuous movement of the product (remember the prefix “pul-“ in the name “pultrusion”).

The combination of pulling force and die temperature gives to the product the exact mechanical and thermal properties required: tensile strength more that 2600 MPa and a glass transition temperature more than 180°C!

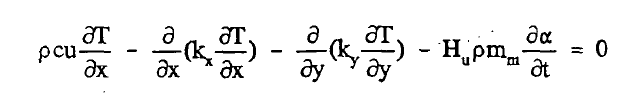

Are you curious to know the relation that links temperature and line speed? Here you will be satisfied!

Where:

- T = temperature of the material

- k = thermal conductivity of the material

- c = heat capacity of the material

- u = pultrusion line speed

- HU = ultimate heat of reaction

- mm = mass fraction of matrix

- α = degree-of-cure

- ρ = density of the material

The independent variables x and y denote longitudinal and transverse directions, respectively. The rate of cure α is a function of temperature and degree-of-cure, therefore it is a function of position, thus satisfying the condition of steady state.

[“Pultrusion Process Characterization” – NASA document NAS8-37193]