Home » Lab » TGA – Thermogravimetric Analysis

TGA – Thermogravimetric Analysis

Thermogravimetric analysis (TGA) measures with very high precision the changes in mass of a material during heating or holding at temperature, providing information on thermal stability and reactions such as solvent loss, oxidation, or degradation up to 1000°C.

Materials, when subjected to heating, can undergo changes in their chemical or physical structure, such as the loss of water or solvents, the emission of gases, or their degradation. These phenomena are often accompanied by a change in mass.

Thermogravimetric analysis (TGA) is a thermal analysis method that monitors the change in mass of a material sample over time (isothermal) and/or with temperature (heating/cooling ramp), as a function of the heating rate, the gas atmosphere present (inert or oxidising), the crucible type, and other parameters.

The instrument in our laboratory allows for the accurate detection of mass changes down to fractions of a microgram. Furthermore, its high sensitivity allows for the determination of the smallest material changes.

These measurements provide information on the thermal stability of the samples and any solid-gas reactions, such as absorption, desorption, oxidation, or reduction.

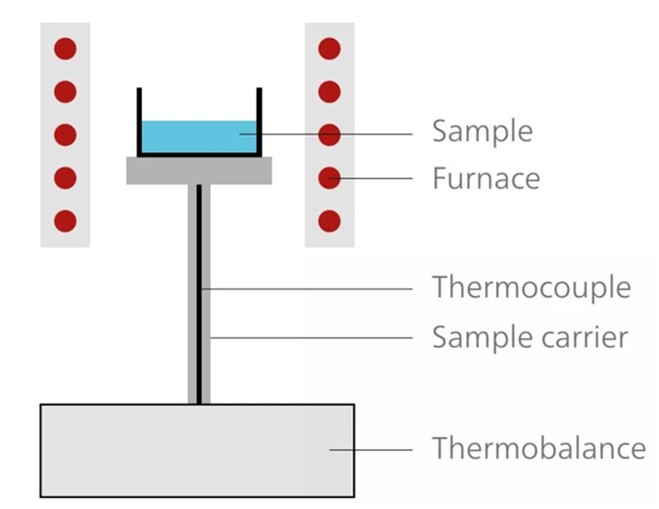

The instrument consists of a thermobalance, which monitors the weight of the analysed sample; a furnace (see Fig. 1) that can house the sample and allows heating to high temperatures (up to 1000°C); a control system, which manages the temperature profiles; and a ventilation system and vacuum pump, used to condition and maintain a controlled atmosphere inside the furnace and to remove any gases produced.

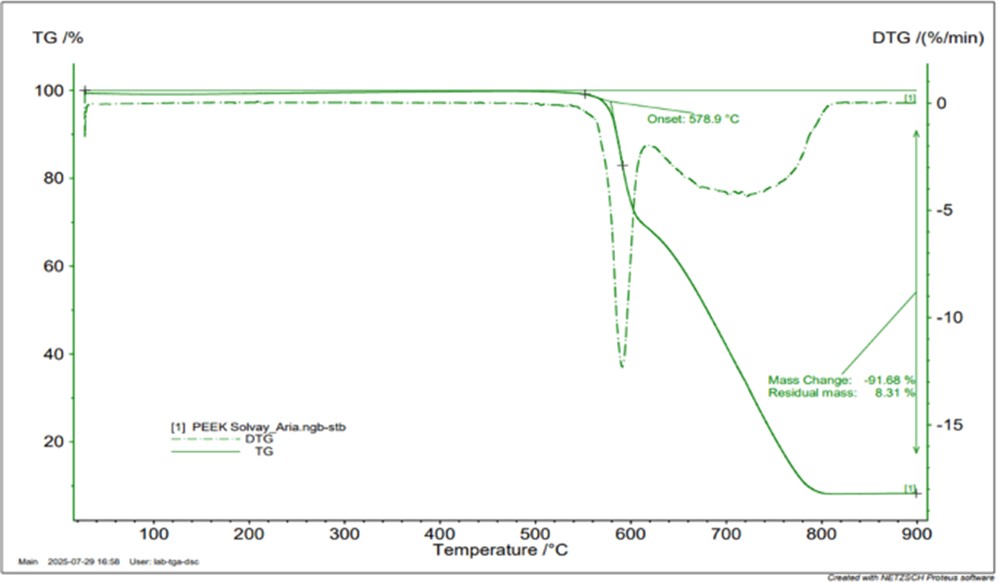

TGA graphic example

The graph shows the behaviour of PEEK, a thermoplastic material, when subjected to heating.

The solid green curve (TG) shows the material’s thermal stability up to approximately 579°C. Above this temperature, a sharp mass loss of about 91.7% is observed, with a carbonaceous residue of 8.3% at 900°C, indicating the polymer’s high thermal resistance.

The dashed green DTG curve (Derivative Thermogravimetry) represents the rate of mass change. It shows a single, well-defined peak in the 590-610°C range, corresponding to the maximum degradation rate. The presence of a single peak confirms that the degradation of PEEK occurs through a single-stage process, confirming that no other components are present in the material.

Related products

-

Enamelled conductors

De Angeli Prodotti enamelled wires are available in copper and aluminum. The configuration possibilities are many: choose the ideal solution for your projects.

Read More → -

Peekvest: Extruded PEEK flat wire

The extruded PEEK cable is positioned as a top-of-the-range solution capable of facing the future challenges of the E-Mobility sector

Read More → -

Thervest Enameled flat wire

A wide range of enamelled wires, a product that boasts a thirty-year tradition of production and now adapted to meet automotive needs

Read More →