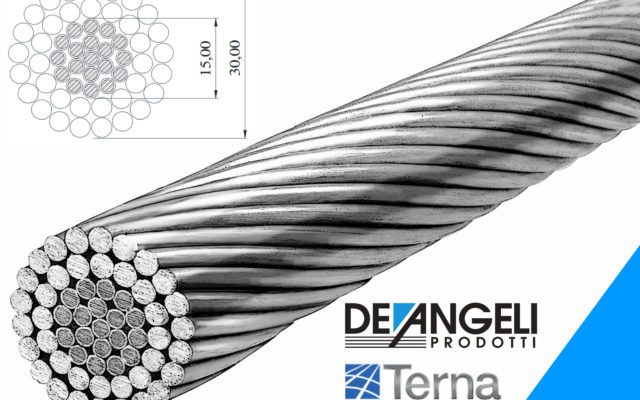

De Angeli Prodotti has developed Expanded conductors, featuring hollow strands that increase diameter without significantly increasing weight, reducing corona effect and improving transmission line efficiency.

De Angeli Prodotti has developed and manufactures Expanded conductors, a technologically advanced solution designed to enhance the performance of overhead power lines and meet the growing needs for efficiency, reliability, and sustainability in transmission networks.

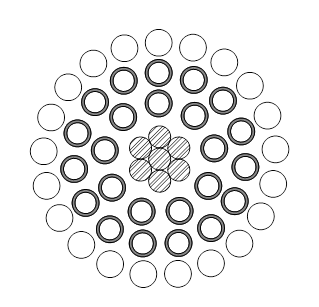

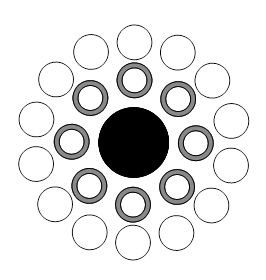

Expanded conductors feature an advanced structure with one or more layers of hollow wires (tubes). This design makes it possible to increase the conductor diameter without a significant increase in weight per meter.

Larger diameter to reduce the corona effect

Increasing the conductor diameter is one of the main factors in reducing the corona effect, a phenomenon that occurs in high- and extra-high-voltage lines when the electric field at the conductor surface reaches critical levels.

A larger diameter allows for a more uniform distribution of the electric field, reducing local field intensity and limiting the ionization of the surrounding air. This results in:

- lower energy losses along the line;

- reduced noise levels;

- mitigation of electromagnetic interference.

Electrical, mechanical, and environmental benefits

In addition to reducing the corona effect, expanded conductors offer several further advantages:

- reduced environmental impact, thanks to lower energy losses, reduced noise, and improved operational reliability;

- optimized weight, enabling installation without significant modifications to existing support structures or, for new lines, the use of lighter supports for the same conductor diameter;

- optimized mechanical performance, with an effective balance of strength, flexibility, and long-term durability;

- higher electrical efficiency, due to more stable behavior at high voltages.

Wide design flexibility

The expanded conductors developed by De Angeli Prodotti can be manufactured with different types of cores, depending on specific application requirements:

- metallic cores made of steel wires, ACS (Aluminium Clad Steel), or ACI (Aluminium Clad Invar);

- carbon-fiber composite cores, ideal for applications requiring high mechanical performance, a low coefficient of thermal expansion, and stability at high operating temperatures.

In addition, conductive layers can be made of aluminum wires, annealed aluminum, aluminum alloys, or thermal-resistant aluminum alloys.

This design flexibility makes expanded conductors suitable both for new transmission lines and for uprating interventions on existing power infrastructure.