The production of insulated products can be achieved by depositing enamel onto the surface of a conductor (copper or aluminium) or by covering the conductor with paper or polymer-based tapes, or even with glass-fibre insulation.

Dielectric insulation allows two different conductors to be placed side-by-side, preventing short circuits during winding, which would otherwise render the finished motor or transformer unusable.

This instrument allows us to verify the dielectric performance of the insulation (enamel and/or paper) by checking the breakdown voltage characteristic.

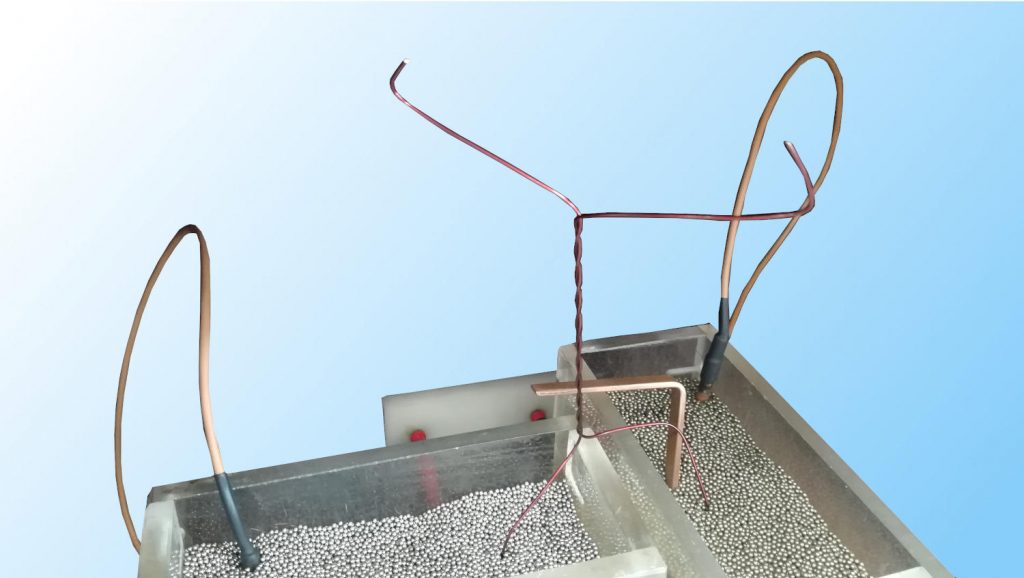

Samples of insulated wire or rectangular wire are prepared in accordance with international standards or client specifications: for wires, a twist sample is created, while for rectangular wires, bends are made along the thickness or width.

- The sample is placed inside a box containing 2mm diameter stainless steel spheres (shot).

- The sample is connected to an electrical voltage source that increases at set rates (up to 500V/s), while the steel is “earthed” (grounded).

- The applied voltage increases continuously until it reaches the value at which it punctures the insulation.

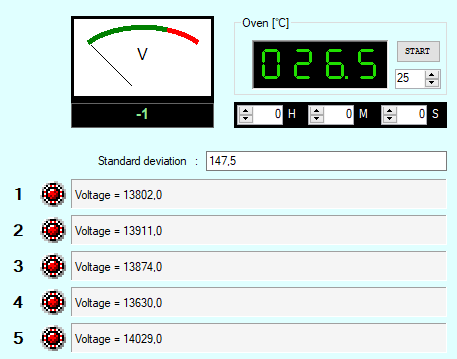

- Da qui registriamo il valore di tensione di perforazione (Break Down Voltage).

Our instrument is capable of performing tests at temperatures up to 250°C.

Test temperature (can reach up to 250°C) and Measured breakdown voltages (average 13.8 kV)

International standards require a minimum BDV value of 2kV for dielectric insulation performance.

The products made in DAP with the best performance are the enamelled rectangular wires intended for manufacturing hairpins for electric vehicle motors (Powertrain e-mobility), which achieve values exceeding 10kV!